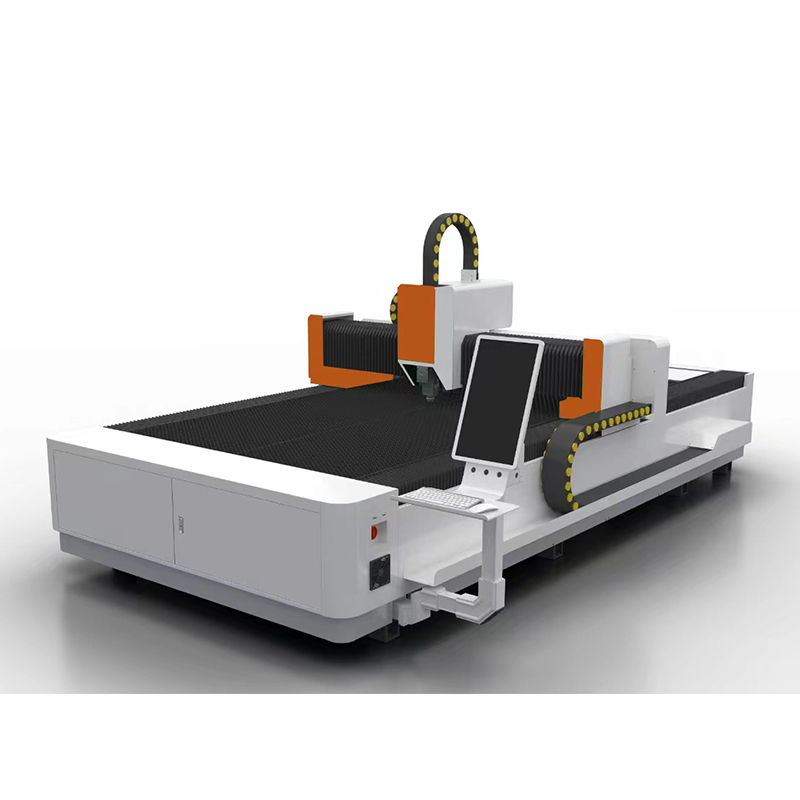

The fiber laser cutting machine is a type of laser cutting equipment that utilizes a fiber laser generator as its light source.A fiber laser incorporates pumping material into the fiber. When a specific wavelength of laser emitted by a semiconductor laser is coupled, it causes the fiber to generate laser light, which is then focused onto the surface of the workpiece. The area of the workpiece illuminated by the laser spot locally melts and vaporizes instantaneously.

Contact Now

Optical Fiber Laser Marker-Miniature can achieve micrometer-level marking precision, meeting the requirements of applications where high marking fineness is needed.The laser beam does not have direct contact with the workpiece surface, avoiding potential physical damage and deformation caused by traditional marking methods.It can be used for marking a variety of materials, including metals, plastics, ceramics, glass, and more.High flexibility: Customizable engraving content, including fonts, sizes, depths, positions, etc., to meet personalized needs.It is usually equipped with a computer

Contact Now

Laser Safety Window is specialized panels crafted to effectively block and absorb laser light, minimizing potential harm to human eyes and skin. They are extensively utilized in fields such as laser processing, medical treatment, and scientific research, ensuring the safety of operators and patients by effectively shielding them from laser exposure. These windows foster a secure working environment, boosting work efficiency and quality by alleviating concerns related to laser hazards.

Contact Now

CO2 laser engraving and cutting machine utilizes CO2 laser technology, comprising a laser generator (producing the beam), an optical path system (directing it to the cutting head), a worktable (supporting and moving the material), a cutting head (focusing the beam), and a cooling system (ensuring the generator operates). This machine boasts high focusing accuracy, fast scanning speeds, and efficient energy conversion with minimal material loss. It is low-cost, easy to maintain, and versatile due to adjustable parameters like laser intensity, frequency, and scanning speed.

Contact Now

The QBH protective cap is vital in fiber laser cutting machines, shielding the laser's crystals and output window from dust, dirt, and contaminants. It prevents damage from metal splashes and impurities, ensuring long service life. Made of high-quality, heat-resistant, corrosion-resistant, and wear-resistant materials, it effectively protects the laser.

Contact Now

The QBH protective cap is an important protective device used in fiber laser cutting machines. It primarily protects the laser's crystals and output window. During the laser cutting process, the protective cap prevents dust, dirt, and other impurities from entering the laser's interior, thereby maintaining the laser's performance and stability.

Contact Now

The QBH protective cap plays a crucial role in fiber laser cutting machines by safeguarding the laser's crystals and output window. It acts as a barrier against dust, dirt, and other contaminants during the cutting process, preserving the laser's performance and stability. Additionally, it protects the laser from damage inflicted by metal splashes and other impurities, thereby prolonging its service life.

Contact Now

The QBH protective cap is essential for fiber laser cutting machines, as it guards the laser's crystals and output window from dust, dirt, and contaminants. It safeguards against metal splashes and impurities, prolonging the laser's lifespan. Constructed from premium, heat-tolerant, corrosion-proof, and durable materials, it offers robust protection.

Contact Now

Laser Safety Window is specialized panels designed to block and absorb laser light, minimizing risks to human eyes and skin. Widely used in laser processing, medical treatment, and research, they protect operators and patients from laser exposure. These windows create a safe work environment, improving efficiency and quality by reducing laser hazard concerns. They also prevent equipment damage and losses due to laser reflections or leaks. Available in different protection levels, they can be customized to suit specific needs, with higher levels offering better protection.

Contact Now

Laser sealing ring consists of a corrosion-resistant spring (typically a stainless metal spring) and a U-shaped filler cloth (usually PTFE or different high-performance polymeric materials) that together structure a sealing ring.

Contact Now

Laser Safety Window is specialized panels designed to effectively block and absorb laser light, reducing potential harm to human eyes and skin. Widely used in laser processing, medical treatment, and scientific research, they safeguard the safety of operators and patients by effectively blocking laser light. These windows provide a safe working environment, enhancing work efficiency and quality by eliminating concerns about laser dangers. Additionally, they prevent equipment damage and other property losses due to laser reflections or leaks.

Contact Now

The laser ceramic ring of a laser device is a vital component connecting the laser head and laser body. Made of alumina ceramic material, it is renowned for its heat and corrosion resistance. This ring serves as a buffer, minimizing stress due to mismatched thermal expansion coefficients, thereby reinforcing the connection between the laser head and body.The high energy and temperature within the laser device pose rigorous demands on its internal materials. The alumina ceramic body of the laser head withstands high-temperature, high-energy lasers without sustaining damage over time.

Contact Now

A Laser Water Chiller is a tailored industrial device for the laser industry, utilizing a water-cooled system to maintain the laser generator's optimal temperature. It works by circulating water through the generator, leveraging water's thermal conductivity and the chiller's refrigeration process to efficiently remove heat.

Contact Now

A Laser Water Chiller is a specialized industrial chiller in the laser industry that maintains the laser generator's temperature through a water-cooled circulation system. It uses water's thermal conductivity and its own refrigeration cycle to circulate water through the laser generator, absorbing heat and dissipating it externally via a condenser.

Contact Now

Laser sensor is an important component in laser equipment or additive manufacturing equipment, primarily used in laser cutting and cladding processes. It rapidly scans the coating with a high-energy laser beam, causing the preset powder to melt and solidify instantaneously, while the base metal melts into a thin layer. Within a narrow region, the interface between the two rapidly undergoes molecular or atomic-level interdiffusion, forming a strong metallurgical bond.

Contact Now

A Laser Water Chiller is a custom-built industrial chiller for the laser industry, employing a water-cooling system to stabilize the laser generator's temperature. By circulating water and harnessing its thermal conductivity alongside the chiller's refrigeration mechanics, it efficiently draws off heat.

Contact Now

Laser protective glasses serve a vital role across various domains including industrial production, medical treatment, scientific research, and more.

Contact Now

The laser sensor is a crucial part of laser and additive manufacturing equipment, particularly in laser cutting and cladding processes. It uses a high-energy laser beam to scan the coating, melting and solidifying the preset powder instantly, while the base metal melts into a thin layer.

Contact Now

Laser Safety Window is specialized panels that block and absorb laser light to safeguard human eyes and skin. Utilized across laser processing, medical treatments, and research, they shield operators and patients from laser exposure. These windows foster a secure work environment, enhancing efficiency and quality by mitigating laser hazards. They also guard against equipment damage and losses caused by laser reflections or leaks. Offered in various protection levels, they can be tailored to meet specific requirements, with higher levels providing superior protection.

Contact Now

A Laser Water Chiller is a specialized industrial chiller designed for the laser industry. It uses a water-cooled system to keep the laser generator at an optimal temperature. By circulating water through the generator and utilizing both water's thermal conductivity and the chiller's refrigeration cycle, it effectively absorbs and dissipates heat externally.

Contact Now

Laser protective glasses play a crucial role in multiple fields, including industrial production, medical treatment, and scientific research. Their key advantages are highlighted as follows:Professional Protective CapabilitiesSpecific Wavelength Protection:Designed to shield against specific laser wavelengths, minimizing eye damage.

Contact Now

D16 Laser Collimating Lens:Laser Collimating Lens is an optical component used to focus the laser beam and maintain the stability and accuracy of the laser path. In laser cutting machines, laser measurement, and other laser processing applications, laser collimating lenses are employed to compress divergent laser beams into parallel beams, thereby enhancing the laser's penetration power and beam quality to ensure precise application of the laser onto the target workpiece. The working principle of a laser collimating lens is primarily based on the refraction of light by the lens.

Contact Now

A Laser Water Chiller is a specialized application of industrial chillers in the laser industry. It utilizes a water-cooled circulation system to cool the laser generator of laser equipment and control its operating temperature, enabling the laser generator to maintain normal operation for extended periods.The working principle of a Laser Water Chiller is based on the thermal conductivity of water and the refrigeration cycle of the chiller.

Contact Now

Laser sealing ring consists of a corrosion-resistant spring (typically a stainless steel spring) and a U-shaped filler material (usually PTFE or other high-performance polymeric materials) that together form a sealing ring.

Contact Now