The handheld laser cleaning machine is versatile, extending beyond mold cleaning to various manufacturing processes. Its widespread adoption across numerous fields is attributed to several remarkable advantages.Firstly, it eliminates the need for cleaning agents and waste disposal, reducing material consumption, operational costs, and environmental and health risks associated with chemical waste.Secondly, the machine provides exceptional precision, enabling efficient cleaning of target areas without damaging surroundings.

Contact Now

Handheld laser cleaning machine is not limited to mold cleaning; they also play a crucial role in the cleaning of various workpieces during the manufacturing process. The reason why this technology can serve as an alternative to traditional cleaning methods and has been widely adopted in numerous fields is that it possesses a series of remarkable advantages.Firstly, laser cleaning machine does not require the use of any cleaning agents or the disposal of waste materials generated after cleaning.

Contact Now

The handheld laser cleaning machine is a multifaceted tool applied in various manufacturing processes beyond mold cleaning. Its popularity stems from several key benefits.One significant advantage is that it eliminates the necessity for cleaning agents and subsequent waste disposal, thus reducing material usage, operational costs, and environmental and health hazards linked to chemical waste.Moreover, the machine offers exceptional precision, enabling targeted cleaning without damaging adjacent areas.

Contact Now

The handheld laser welding machine offers flexibility in welding any part and angle of the workpiece, breaking the limitations of workbenches.With its small size and lightweight design, it is easy to carry and move, making it suitable for various on-site welding needs.During welding, the heat-affected zone is small, preventing issues such as workpiece deformation, discoloration, and marks on the back.

Contact Now

Stable Variable Machine all-in-one is a device that integrates a voltage stabilizer and a transformer into a single enclosure, utilizing a modular wiring configuration that facilitates easier maintenance and saves space.This device operates in a mode of first stabilizing the voltage and then transforming it, ensuring that the output voltage remains within the normal set range.

Contact Now

CO2 laser engraving and cutting machine is a device that utilizes CO2 laser technology.CO2 laser engraving and cutting machine mainly consists of a laser generator, an optical path system, a worktable, a cutting head, and a cooling system.

Contact Now

CO2 laser engraving and cutting machine uses CO2 laser technology, featuring a laser generator, optical path system, worktable, cutting head, and cooling system. It offers high accuracy, fast scanning speed, and efficient energy conversion, minimizing material loss. Adjustable parameters allow versatility in cutting different materials.

Contact Now

CO2 laser engraving and cutting machine is a device leveraging CO2 laser technology. Its main components include a laser generator (producing the laser beam), an optical path system (transmitting the beam to the cutting head), a worktable (supporting and moving the material), a cutting head (focusing the beam for cutting), and a cooling system (ensuring the generator operates normally).This machine boasts high focusing accuracy for precise engraving and cutting, rapid scanning speed for enhanced processing efficiency, and high energy conversion efficiency, minimizing material loss.

Contact Now

Laser protective glasses play a crucial role in industrial production, medical treatment, scientific research, and other fields. Their main advantages are reflected in the following aspects:Professional Protective PerformanceTargeted Protection:Laser protective glasses can efficiently protect against specific wavelengths of laser light, reducing or avoiding damage to the eyes.Different types of laser protective glasses are designed for different wavelengths of laser light.

Contact Now

CO2 laser engraving and cutting machine employs CO2 laser technology.Its primary components include a laser generator (which produces the laser beam), an optical path system (directs the beam to the cutting head), a worktable (supports and moves the material), a cutting head (focuses the beam for cutting), and a cooling system (keeps the laser generator operational).This machine offers high focusing accuracy for precise cutting and engraving, fast scanning speeds for efficient processing, and high energy conversion efficiency with minimal material loss.It is easy to maintain and oper

Contact Now

CO2 laser engraving and cutting machine utilizes CO2 laser technology, comprising a laser generator (producing the beam), an optical path system (directing it to the cutting head), a worktable (supporting and moving the material), a cutting head (focusing the beam), and a cooling system (ensuring the generator operates). This machine boasts high focusing accuracy, fast scanning speeds, and efficient energy conversion with minimal material loss. It is low-cost, easy to maintain, and versatile due to adjustable parameters like laser intensity, frequency, and scanning speed.

Contact Now

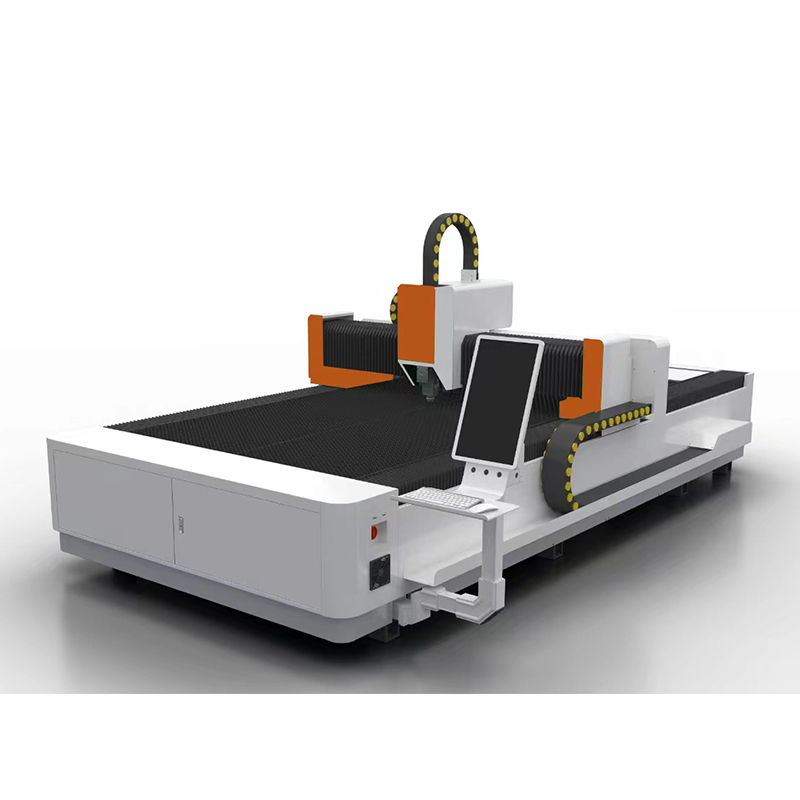

The fiber laser cutting machine is a type of laser cutting equipment that utilizes a fiber laser generator as its light source.A fiber laser incorporates pumping material into the fiber. When a specific wavelength of laser emitted by a semiconductor laser is coupled, it causes the fiber to generate laser light, which is then focused onto the surface of the workpiece. The area of the workpiece illuminated by the laser spot locally melts and vaporizes instantaneously.

Contact Now

Raytools laser nozzles are primarily used to connect the laser cutting head with the TRA component's capacitive sensor, ensuring the smooth operation of the laser cutting machine.

Contact Now

Laser sensor is an essential factor in laser tools or additive manufacturing equipment, exceptionally used in laser slicing and cladding processes. It hastily scans the coating with a high-energy laser beam, inflicting the preset powder to soften and solidify instantaneously, whilst the base metallic melts into a skinny layer.

Contact Now

Laser Safety Window is specialized panels designed to effectively block and absorb laser light, reducing potential harm to human eyes and skin. Widely used in laser processing, medical treatment, and scientific research, they safeguard the safety of operators and patients by effectively blocking laser light. These windows provide a safe working environment, enhancing work efficiency and quality by eliminating concerns about laser dangers. Additionally, they prevent equipment damage and other property losses due to laser reflections or leaks.

Contact Now

A Laser Water Chiller is a tailored industrial device for the laser industry, utilizing a water-cooled system to maintain the laser generator's optimal temperature. It works by circulating water through the generator, leveraging water's thermal conductivity and the chiller's refrigeration process to efficiently remove heat.

Contact Now

Laser sensor is an important component in laser equipment or additive manufacturing equipment, primarily used in laser cutting and cladding processes. It rapidly scans the coating with a high-energy laser beam, causing the preset powder to melt and solidify instantaneously, while the base metal melts into a thin layer. Within a narrow region, the interface between the two rapidly undergoes molecular or atomic-level interdiffusion, forming a strong metallurgical bond.

Contact Now

Laser Safety Window is specialized panels designed to block and absorb laser light, minimizing risks to human eyes and skin. Widely used in laser processing, medical treatment, and research, they protect operators and patients from laser exposure. These windows create a safe work environment, improving efficiency and quality by reducing laser hazard concerns. They also prevent equipment damage and losses due to laser reflections or leaks. Available in different protection levels, they can be customized to suit specific needs, with higher levels offering better protection.

Contact Now

Laser focus lens, also known as laser focusing mirrors or lenses, are optical components that adjust the angle and focal point of a laser beam. They enhance the beam's penetration and energy density by converging a divergent laser beam into a small spot. Based on light refraction and focusing effects, these lenses change the beam's direction of propagation due to the lens material's refractive index and shape. Specifically, the curvature and shape of the lens refract the incident beam, causing it to converge at the focal point.

Contact Now

A Laser Water Chiller is an industrial chiller specifically designed for the laser industry. It employs a water-cooled circulation system to regulate the operating temperature of the laser generator, ensuring sustained normal operation. By leveraging water's thermal conductivity and the chiller's refrigeration cycle, the chiller circulates cooling water through the laser generator to absorb heat and dissipate it externally via a condenser.

Contact Now

D20 Laser Collimating LensLaser Collimating Lens is an optical factor used to focal point the laser beam and preserve the steadiness and accuracy of the laser path.

Contact Now

Sup AS Laser Welding Nozzle:Laser welding nozzle is a crucial component used in the laser welding process.

Contact Now

A Laser Water Chiller is a custom-built industrial chiller for the laser industry, employing a water-cooling system to stabilize the laser generator's temperature. By circulating water and harnessing its thermal conductivity alongside the chiller's refrigeration mechanics, it efficiently draws off heat.

Contact Now

The laser nozzle is accountable for retaining the distance between the laser head and the workpiece, guiding the auxiliary fuel to ignore easily via the workpiece being cut, and growing excessive strain at the nozzle outlet to speed up the reducing speed. It additionally consists of away molten slag and protects the inside lenses of the laser head.

Contact Now