Sup Laser Sealing RingLaser sealing ring consists of a corrosion-resistant spring (typically a stainless metal spring) and a U-shaped filler cloth (usually PTFE or different high-performance polymeric materials) that together structure a sealing ring. This seal graph combines the homes of metallic and plastic (or polymeric material) to supply outstanding sealing effect.

Contact Now

Kirin WSX AoSen Laser Sealing RingLaser sealing ring consists of a corrosion-resistant spring (typically a stainless steel spring) and a U-shaped filler material (usually PTFE or other high-performance polymeric materials) that together form a sealing ring.

Contact Now

Laser sealing ring consists of a corrosion-resistant spring (typically a stainless metal spring) and a U-shaped filler cloth (usually PTFE or different high-performance polymeric materials) that together structure a sealing ring.

Contact Now

Laser sealing ring consists of a corrosion-resistant spring (typically a stainless steel spring) and a U-shaped filler material (usually PTFE or other high-performance polymeric materials) that together form a sealing ring.

Contact Now

The laser ceramic ring of a laser device is a vital component connecting the laser head and laser body. Made of alumina ceramic material, it is renowned for its heat and corrosion resistance. This ring serves as a buffer, minimizing stress due to mismatched thermal expansion coefficients, thereby reinforcing the connection between the laser head and body.The high energy and temperature within the laser device pose rigorous demands on its internal materials. The alumina ceramic body of the laser head withstands high-temperature, high-energy lasers without sustaining damage over time.

Contact Now

Laser ceramic ring of the laser head refers to the component used to connect the laser head and the laser body in a laser device. It is typically made of alumina ceramic material, known for its heat resistance and corrosion resistance. In a laser device, the ceramic body of the laser head is one of the core components, playing a crucial role.Laser ceramic ring of the laser head is a key component connecting the laser head and the laser body.

Contact Now

Laser ceramic ring of the laser head refers to the issue used to join the laser head and the laser physique in a laser device. It is commonly made of alumina ceramic material, acknowledged for its warmth resistance and corrosion resistance. In a laser device, the ceramic physique of the laser head is one of the core components, enjoying a vital role.Laser ceramic ring of the laser head is a key element connecting the laser head and the laser body.

Contact Now

The laser ceramic ring in a laser device is crucial for connecting the laser head and body. Made of heat and corrosion-resistant alumina ceramic, it acts as a buffer to reduce stress from mismatched thermal expansion coefficients, strengthening the connection. The high energy and temperature within the device require robust internal materials, and the alumina ceramic body of the laser head meets this challenge, enduring high-temperature, high-energy lasers without damage.

Contact Now

CO2 laser engraving and cutting machine is a device that utilizes CO2 laser technology.CO2 laser engraving and cutting machine mainly consists of a laser generator, an optical path system, a worktable, a cutting head, and a cooling system.

Contact Now

CO2 laser engraving and cutting machine employs CO2 laser technology.Its primary components include a laser generator (which produces the laser beam), an optical path system (directs the beam to the cutting head), a worktable (supports and moves the material), a cutting head (focuses the beam for cutting), and a cooling system (keeps the laser generator operational).This machine offers high focusing accuracy for precise cutting and engraving, fast scanning speeds for efficient processing, and high energy conversion efficiency with minimal material loss.It is easy to maintain and oper

Contact Now

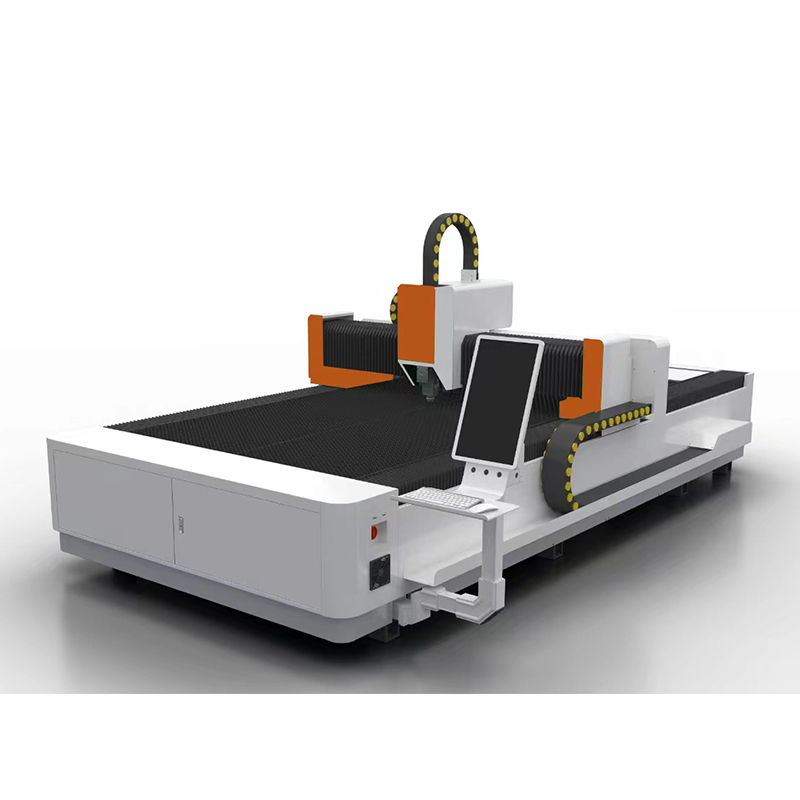

The fiber laser cutting machine is a type of laser cutting equipment that utilizes a fiber laser generator as its light source.A fiber laser incorporates pumping material into the fiber. When a specific wavelength of laser emitted by a semiconductor laser is coupled, it causes the fiber to generate laser light, which is then focused onto the surface of the workpiece. The area of the workpiece illuminated by the laser spot locally melts and vaporizes instantaneously.

Contact Now

CO2 laser engraving and cutting machine utilizes CO2 laser technology, comprising a laser generator (producing the beam), an optical path system (directing it to the cutting head), a worktable (supporting and moving the material), a cutting head (focusing the beam), and a cooling system (ensuring the generator operates). This machine boasts high focusing accuracy, fast scanning speeds, and efficient energy conversion with minimal material loss. It is low-cost, easy to maintain, and versatile due to adjustable parameters like laser intensity, frequency, and scanning speed.

Contact Now

CO2 laser engraving and cutting machine uses CO2 laser technology, featuring a laser generator, optical path system, worktable, cutting head, and cooling system. It offers high accuracy, fast scanning speed, and efficient energy conversion, minimizing material loss. Adjustable parameters allow versatility in cutting different materials.

Contact Now

The laser nozzle is crucial in laser cutting, managing distance, directing gas flow, and enhancing cutting speed by creating high pressure.

Contact Now

Raytools laser nozzles serve a vital function in laser cutting machines by connecting the laser cutting head with the TRA component's capacitive sensor, thereby ensuring seamless operation.

Contact Now

CO2 laser engraving and cutting machine is a device leveraging CO2 laser technology. Its main components include a laser generator (producing the laser beam), an optical path system (transmitting the beam to the cutting head), a worktable (supporting and moving the material), a cutting head (focusing the beam for cutting), and a cooling system (ensuring the generator operates normally).This machine boasts high focusing accuracy for precise engraving and cutting, rapid scanning speed for enhanced processing efficiency, and high energy conversion efficiency, minimizing material loss.

Contact Now

The laser nozzle plays a crucial role in laser cutting by maintaining the distance between the laser head and the workpiece, directing auxiliary gas flow, creating high pressure at the outlet to speed up cutting, removing molten slag, and protecting the laser head's internal lenses.

Contact Now

The laser nozzle is vital in laser cutting, managing distance, directing gas flow, creating high pressure for faster cutting, removing slag, and protecting lenses.

Contact Now

The laser nozzle plays a vital role in laser cutting by managing distance, directing gas flow, boosting speed, removing slag, and safeguarding lenses.

Contact Now

Controlling and Optimizing Laser Cutting with NozzlesThe nozzle plays a crucial role in laser cutting by precisely controlling the focusing position of the laser beam on the workpiece surface, ensuring accurate application of laser energy.Through its design, the nozzle accelerates the laser beam, causing the irradiated area to melt and vaporize, thereby forming a cutting gap.It also guides auxiliary gases (e.g., nitrogen, oxygen) smoothly through the workpiece, creating high pressure near the outlet that enhances cutting speed while effectively removing slag and heat, thus protecting the laser

Contact Now

The laser nozzle is essential in laser cutting, managing distance, directing gas flow, enhancing speed, removing slag, and protecting lenses. It directly affects cutting quality.Types:Single-layer: Uses nitrogen for stainless steel and aluminum alloy.Double-layer: Uses oxygen for carbon steel.Aperture size:Small: Best for thin plates, finer finish, may leave slag.Large: Suitable for thick plates, stable cutting, risks lens damage.Coaxiality between the nozzle and laser beam is crucial for better cutting, especially with thick workpieces.

Contact Now

The laser nozzle is pivotal in laser cutting, managing distance, controlling gas flow, enhancing speed, removing slag, and protecting lenses, all of which influence cutting quality.Types include:Single-layer: Uses nitrogen for stainless steel and aluminum alloy applications.Double-layer: Employs oxygen for cutting carbon steel.When considering aperture size:Small: Best for thin plates, delivering a finer finish but may result in slag residue.Large: Suitable for thick plates, providing stable cutting but with potential risk of lens damage from sparks.Proper coaxial alignment between the nozzle

Contact Now

The QBH protective cap plays a crucial role in fiber laser cutting machines by safeguarding the laser's crystals and output window. It acts as a barrier against dust, dirt, and other contaminants during the cutting process, preserving the laser's performance and stability. Additionally, it protects the laser from damage inflicted by metal splashes and other impurities, thereby prolonging its service life.

Contact Now

The QBH protective cap is an important protective device used in fiber laser cutting machines. It primarily protects the laser's crystals and output window. During the laser cutting process, the protective cap prevents dust, dirt, and other impurities from entering the laser's interior, thereby maintaining the laser's performance and stability.

Contact Now