Stable Variable Machine all-in-one is a device that integrates a voltage stabilizer and a transformer into a single enclosure, utilizing a modular wiring configuration that facilitates easier maintenance and saves space.This device operates in a mode of first stabilizing the voltage and then transforming it, ensuring that the output voltage remains within the normal set range.

Contact Now

The three-phase automatic AC compensation voltage stabilizer is a power voltage stabilizing device that combines modern electronic technology and automatic control technology. It can monitor grid voltage fluctuations in real-time and automatically adjust the output voltage to maintain its stability.The voltage sensor monitors the fluctuations in the grid voltage in real-time. The control system receives signals transmitted by the voltage sensor and compares them with the set stable voltage to calculate the voltage value that needs to be compensated.

Contact Now

The handheld laser cleaning machine is versatile, extending beyond mold cleaning to various manufacturing processes. Its widespread adoption across numerous fields is attributed to several remarkable advantages.Firstly, it eliminates the need for cleaning agents and waste disposal, reducing material consumption, operational costs, and environmental and health risks associated with chemical waste.Secondly, the machine provides exceptional precision, enabling efficient cleaning of target areas without damaging surroundings.

Contact Now

The handheld laser cleaning machine is a multifaceted tool applied in various manufacturing processes beyond mold cleaning. Its popularity stems from several key benefits.One significant advantage is that it eliminates the necessity for cleaning agents and subsequent waste disposal, thus reducing material usage, operational costs, and environmental and health hazards linked to chemical waste.Moreover, the machine offers exceptional precision, enabling targeted cleaning without damaging adjacent areas.

Contact Now

Handheld laser cleaning machine is not limited to mold cleaning; they also play a crucial role in the cleaning of various workpieces during the manufacturing process. The reason why this technology can serve as an alternative to traditional cleaning methods and has been widely adopted in numerous fields is that it possesses a series of remarkable advantages.Firstly, laser cleaning machine does not require the use of any cleaning agents or the disposal of waste materials generated after cleaning.

Contact Now

CO2 laser engraving and cutting machine is a device that utilizes CO2 laser technology.CO2 laser engraving and cutting machine mainly consists of a laser generator, an optical path system, a worktable, a cutting head, and a cooling system.

Contact Now

CO2 laser engraving and cutting machine uses CO2 laser technology, featuring a laser generator, optical path system, worktable, cutting head, and cooling system. It offers high accuracy, fast scanning speed, and efficient energy conversion, minimizing material loss. Adjustable parameters allow versatility in cutting different materials.

Contact Now

The handheld laser welding machine offers flexibility in welding any part and angle of the workpiece, breaking the limitations of workbenches.With its small size and lightweight design, it is easy to carry and move, making it suitable for various on-site welding needs.During welding, the heat-affected zone is small, preventing issues such as workpiece deformation, discoloration, and marks on the back.

Contact Now

CO2 laser engraving and cutting machine is a device leveraging CO2 laser technology. Its main components include a laser generator (producing the laser beam), an optical path system (transmitting the beam to the cutting head), a worktable (supporting and moving the material), a cutting head (focusing the beam for cutting), and a cooling system (ensuring the generator operates normally).This machine boasts high focusing accuracy for precise engraving and cutting, rapid scanning speed for enhanced processing efficiency, and high energy conversion efficiency, minimizing material loss.

Contact Now

CO2 laser engraving and cutting machine employs CO2 laser technology.Its primary components include a laser generator (which produces the laser beam), an optical path system (directs the beam to the cutting head), a worktable (supports and moves the material), a cutting head (focuses the beam for cutting), and a cooling system (keeps the laser generator operational).This machine offers high focusing accuracy for precise cutting and engraving, fast scanning speeds for efficient processing, and high energy conversion efficiency with minimal material loss.It is easy to maintain and oper

Contact Now

CO2 laser engraving and cutting machine utilizes CO2 laser technology, comprising a laser generator (producing the beam), an optical path system (directing it to the cutting head), a worktable (supporting and moving the material), a cutting head (focusing the beam), and a cooling system (ensuring the generator operates). This machine boasts high focusing accuracy, fast scanning speeds, and efficient energy conversion with minimal material loss. It is low-cost, easy to maintain, and versatile due to adjustable parameters like laser intensity, frequency, and scanning speed.

Contact Now

Laser Sensor Cable is a type of cable designed for transmitting RF signals, with the purpose of ensuring efficient and stable transmission of RF signals to the laser, thereby driving it to produce high-quality laser beams.In fields such as communications, medical, and industrial applications, laser RF cables play a crucial role.

Contact Now

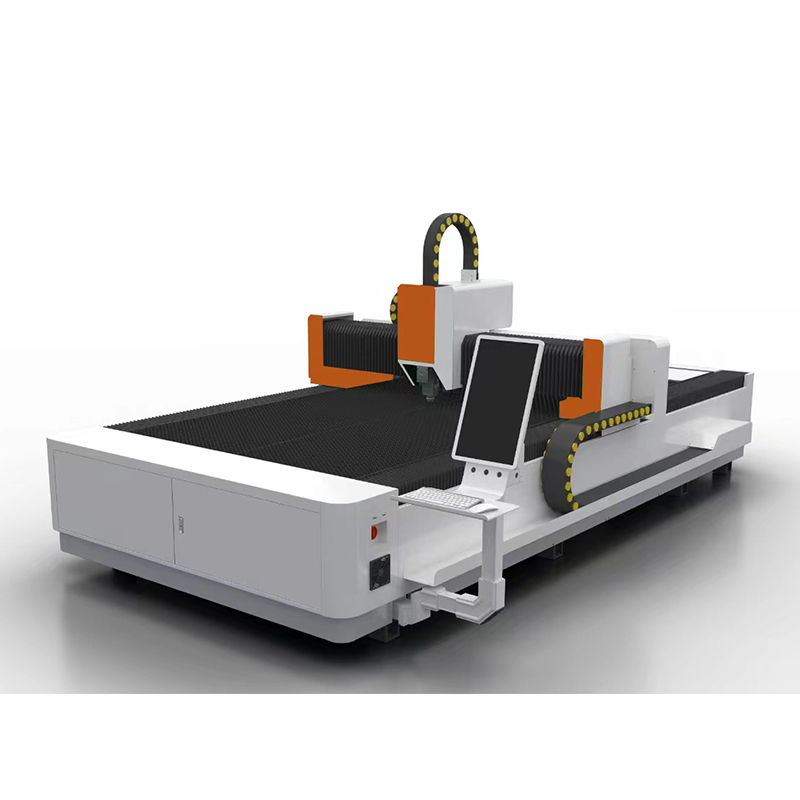

The fiber laser cutting machine is a type of laser cutting equipment that utilizes a fiber laser generator as its light source.A fiber laser incorporates pumping material into the fiber. When a specific wavelength of laser emitted by a semiconductor laser is coupled, it causes the fiber to generate laser light, which is then focused onto the surface of the workpiece. The area of the workpiece illuminated by the laser spot locally melts and vaporizes instantaneously.

Contact Now

The laser nozzle is essential in laser cutting, managing distance, directing gas flow, enhancing speed, removing slag, and protecting lenses. It directly affects cutting quality.Types:Single-layer: Uses nitrogen for stainless steel and aluminum alloy.Double-layer: Uses oxygen for carbon steel.Aperture size:Small: Best for thin plates, finer finish, may leave slag.Large: Suitable for thick plates, stable cutting, risks lens damage.Coaxiality between the nozzle and laser beam is crucial for better cutting, especially with thick workpieces.

Contact Now

The laser nozzle is pivotal in laser cutting, managing distance, controlling gas flow, enhancing speed, removing slag, and protecting lenses, all of which influence cutting quality.Types include:Single-layer: Uses nitrogen for stainless steel and aluminum alloy applications.Double-layer: Employs oxygen for cutting carbon steel.When considering aperture size:Small: Best for thin plates, delivering a finer finish but may result in slag residue.Large: Suitable for thick plates, providing stable cutting but with potential risk of lens damage from sparks.Proper coaxial alignment between the nozzle

Contact Now

Raytools laser nozzles are primarily used to connect the laser cutting head with the TRA component's capacitive sensor, ensuring the smooth operation of the laser cutting machine.

Contact Now

Control the focusing position of the laser beam:The nozzle can precisely control the focusing position of the laser beam on the workpiece surface, ensuring that the laser energy is accurately applied to the area that needs to be cut.Accelerate the laser beam:Through the design of the nozzle, the laser beam can be accelerated, causing the irradiated area to melt and vaporize, forming a cutting gap.Guide the gas flow:The nozzle can guide auxiliary gases (such as nitrogen, oxygen, etc.) to pass smoothly through the workpiece being cut, and form high pressure near the nozzle outlet, which accelera

Contact Now

Laser Safety Goggle, also known as laser safety glasses or anti-laser glasses, are specialized protective eyewear made from unique optical materials. They are designed to absorb and scatter laser beams while maintaining high visible light transmittance and converting laser energy to heat. The lens is specially treated to reduce energy density and protect the eyes.

Contact Now

Laser Safety Goggle, also known as laser safety glasses or anti-laser glasses, are specialized protective eyewear crafted from unique optical materials. Their design enables them to absorb and scatter laser beams, allowing for high transmittance of visible light while converting laser energy into heat. The lens surface undergoes special treatment to decrease energy density and minimize potential eye damage. These goggles provide customized protection for specific laser wavelengths and intense light sources, ensuring clear vision and accurate color perception.

Contact Now

Laser safety goggles are specialized eyewear designed to protect the eyes from laser radiation.Also referred to as laser safety glasses or anti-laser glasses, their primary purpose is to prevent or minimize laser-related eye damage.

Contact Now

Laser safety goggles are specialized eyewear designed to protect the eyes from the harmful effects of laser radiation. Also known as laser safety glasses or anti-laser glasses, their main function is to reduce or prevent laser-induced damage to the eyes. These goggles use advanced optical materials and designs to absorb and disperse laser beams, providing effective eye protection.Crafted from specialized optical materials, the lenses offer high visible light transmittance while keeping reflectance low.

Contact Now

Product description:Laser safety goggles are specially designed eyewear intended to protect the eyes from laser radiation. Also referred to as laser safety glasses or anti-laser glasses, their primary purpose is to prevent or mitigate laser damage to the eyes. They accomplish this through the effective absorption and scattering of laser beams, utilizing specialized optical materials and design.The lenses are generally crafted from unique optical materials that offer high transmittance and low reflectance.

Contact Now

Laser safety goggles, also referred to as laser safety glasses or anti-laser glasses, are specialized protective eyewear made from advanced optical materials. Designed to absorb and diffuse laser beams, they maintain high visible light transmittance while converting laser energy into heat. The lenses are treated to reduce energy density, providing essential eye protection. Tailored for specific laser wavelengths and high-intensity light, these goggles ensure clear vision and accurate color perception.

Contact Now

Laser Safety Goggle, known alternately as laser safety glasses or anti-laser glasses, are specialized eye protection devices made from unique optical materials. They are designed to absorb and scatter laser beams, allowing high transmittance of visible light while converting laser energy into heat. The lens surface is specially treated to reduce energy density and minimize eye damage. These goggles offer tailored protection against specific laser wavelengths and intense light sources, ensuring clear vision and accurate color perception.

Contact Now