Precision Purification Compensation Voltage Stabilizer is a high-performance AC power supply voltage stabilizing device that integrates multiple functions such as purification, voltage stabilization, anti-interference, and automatic protection.Precision Purification Compensation Voltage Stabilizer utilizes advanced techniques such as combined winding compensation, non-contact switches, and microprocessor-controlled AC voltage stabilization to precisely stabilize and purify the input AC power supply.

Contact Now

The three-phase automatic AC compensation voltage stabilizer is a power voltage stabilizing device that combines modern electronic technology and automatic control technology. It can monitor grid voltage fluctuations in real-time and automatically adjust the output voltage to maintain its stability.The voltage sensor monitors the fluctuations in the grid voltage in real-time. The control system receives signals transmitted by the voltage sensor and compares them with the set stable voltage to calculate the voltage value that needs to be compensated.

Contact Now

Stable Variable Machine all-in-one is a device that integrates a voltage stabilizer and a transformer into a single enclosure, utilizing a modular wiring configuration that facilitates easier maintenance and saves space.This device operates in a mode of first stabilizing the voltage and then transforming it, ensuring that the output voltage remains within the normal set range.

Contact Now

Industrial Personal Computer (IPC) is a specialized computing device tailored for industrial automation control systems. It serves multiple industrial sectors including manufacturing, energy production, transportation, medical equipment, and building automation, aimed at enhancing production efficiency, ensuring safety, and minimizing operational costs.The IPC is capable of collecting real-time operational data from various industrial equipment and displaying it to operators through a visual interface.

Contact Now

Industrial Personal Computer (IPC) is a specialized computing device designed for industrial automation control systems.

Contact Now

Industrial Personal Computer (IPC) is a specialized device for industrial automation in sectors like manufacturing, energy, transportation, medical equipment, and building automation. It collects and displays real-time data to enhance efficiency, ensure safety, and reduce costs.

Contact Now

Industrial Personal Computer (IPC) is a specialized device for industrial automation, serving sectors like manufacturing, energy, transportation, medical equipment, and building automation. It enhances efficiency, ensures safety, and reduces costs by collecting and displaying real-time operational data via large touchscreen displays or control panels. Designed with reliable hardware and anti-interference features, the IPC operates stably in harsh conditions.

Contact Now

Industrial Personal Computer (IPC) is a specialized computing device designed for industrial automation control systems.It is commonly used in industrial fields such as manufacturing, energy production, transportation systems, medical equipment, building automation, etc., to improve production efficiency, ensure safety, and reduce operational costs.An IPC can collect real-time operational data from various industrial equipment and present it to operators through a visual interface.Equipped with large touchscreen displays or dedicated control panels, an IPC provides an intuitive interface for o

Contact Now

Industrial Personal Computer (IPC) is a specialized device for industrial automation across various sectors such as manufacturing, energy, transportation, medical equipment, and building automation. It enhances efficiency, ensures safety, and reduces costs by collecting and displaying real-time data. Designed for harsh conditions, it features reliable hardware and anti-interference capabilities.

Contact Now

Optical Fiber Laser Marker-Miniature can achieve micrometer-level marking precision, meeting the requirements of applications where high marking fineness is needed.The laser beam does not have direct contact with the workpiece surface, avoiding potential physical damage and deformation caused by traditional marking methods.It can be used for marking a variety of materials, including metals, plastics, ceramics, glass, and more.High flexibility: Customizable engraving content, including fonts, sizes, depths, positions, etc., to meet personalized needs.It is usually equipped with a computer

Contact Now

The handheld laser cleaning machine is versatile, extending beyond mold cleaning to various manufacturing processes. Its widespread adoption across numerous fields is attributed to several remarkable advantages.Firstly, it eliminates the need for cleaning agents and waste disposal, reducing material consumption, operational costs, and environmental and health risks associated with chemical waste.Secondly, the machine provides exceptional precision, enabling efficient cleaning of target areas without damaging surroundings.

Contact Now

The handheld laser cleaning machine is a multifaceted tool applied in various manufacturing processes beyond mold cleaning. Its popularity stems from several key benefits.One significant advantage is that it eliminates the necessity for cleaning agents and subsequent waste disposal, thus reducing material usage, operational costs, and environmental and health hazards linked to chemical waste.Moreover, the machine offers exceptional precision, enabling targeted cleaning without damaging adjacent areas.

Contact Now

CO2 laser engraving and cutting machine is a device that utilizes CO2 laser technology.CO2 laser engraving and cutting machine mainly consists of a laser generator, an optical path system, a worktable, a cutting head, and a cooling system.

Contact Now

CO2 laser engraving and cutting machine is a device leveraging CO2 laser technology. Its main components include a laser generator (producing the laser beam), an optical path system (transmitting the beam to the cutting head), a worktable (supporting and moving the material), a cutting head (focusing the beam for cutting), and a cooling system (ensuring the generator operates normally).This machine boasts high focusing accuracy for precise engraving and cutting, rapid scanning speed for enhanced processing efficiency, and high energy conversion efficiency, minimizing material loss.

Contact Now

CO2 laser engraving and cutting machine employs CO2 laser technology.Its primary components include a laser generator (which produces the laser beam), an optical path system (directs the beam to the cutting head), a worktable (supports and moves the material), a cutting head (focuses the beam for cutting), and a cooling system (keeps the laser generator operational).This machine offers high focusing accuracy for precise cutting and engraving, fast scanning speeds for efficient processing, and high energy conversion efficiency with minimal material loss.It is easy to maintain and oper

Contact Now

CO2 laser engraving and cutting machine utilizes CO2 laser technology, comprising a laser generator (producing the beam), an optical path system (directing it to the cutting head), a worktable (supporting and moving the material), a cutting head (focusing the beam), and a cooling system (ensuring the generator operates). This machine boasts high focusing accuracy, fast scanning speeds, and efficient energy conversion with minimal material loss. It is low-cost, easy to maintain, and versatile due to adjustable parameters like laser intensity, frequency, and scanning speed.

Contact Now

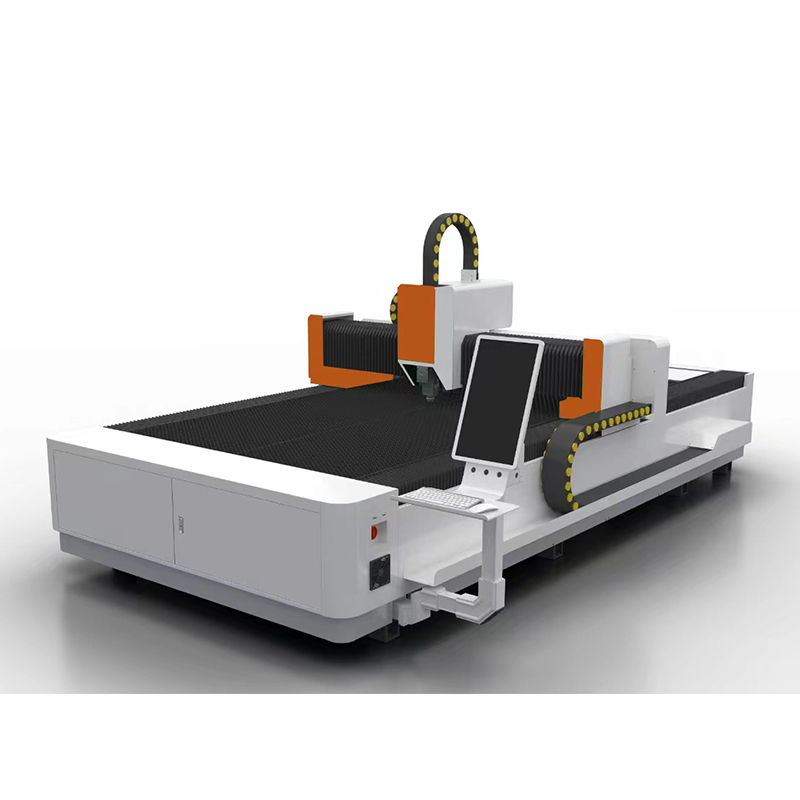

The fiber laser cutting machine is a type of laser cutting equipment that utilizes a fiber laser generator as its light source.A fiber laser incorporates pumping material into the fiber. When a specific wavelength of laser emitted by a semiconductor laser is coupled, it causes the fiber to generate laser light, which is then focused onto the surface of the workpiece. The area of the workpiece illuminated by the laser spot locally melts and vaporizes instantaneously.

Contact Now

Handheld laser cleaning machine is not limited to mold cleaning; they also play a crucial role in the cleaning of various workpieces during the manufacturing process. The reason why this technology can serve as an alternative to traditional cleaning methods and has been widely adopted in numerous fields is that it possesses a series of remarkable advantages.Firstly, laser cleaning machine does not require the use of any cleaning agents or the disposal of waste materials generated after cleaning.

Contact Now

A Laser Water Chiller is a tailored industrial device for the laser industry, utilizing a water-cooled system to maintain the laser generator's optimal temperature. It works by circulating water through the generator, leveraging water's thermal conductivity and the chiller's refrigeration process to efficiently remove heat.

Contact Now

Laser protective glasses play a crucial role in industrial production, medical treatment, scientific research, and other fields. Their main advantages are reflected in the following aspects:Professional Protective PerformanceTargeted Protection:Laser protective glasses can efficiently protect against specific wavelengths of laser light, reducing or avoiding damage to the eyes.Different types of laser protective glasses are designed for different wavelengths of laser light.

Contact Now

Laser protective glasses play a crucial role in multiple fields, including industrial production, medical treatment, and scientific research. Their key advantages are highlighted as follows:Professional Protective CapabilitiesSpecific Wavelength Protection:Designed to shield against specific laser wavelengths, minimizing eye damage.

Contact Now

The laser sensor is a crucial part of laser and additive manufacturing equipment, particularly in laser cutting and cladding processes. It uses a high-energy laser beam to scan the coating, melting and solidifying the preset powder instantly, while the base metal melts into a thin layer.

Contact Now

A Laser Water Chiller is an industrial chiller specifically designed for the laser industry. It employs a water-cooled circulation system to regulate the operating temperature of the laser generator, ensuring sustained normal operation. By leveraging water's thermal conductivity and the chiller's refrigeration cycle, the chiller circulates cooling water through the laser generator to absorb heat and dissipate it externally via a condenser.

Contact Now

Laser ceramic ring of the laser head refers to the component used to connect the laser head and the laser body in a laser device. It is typically made of alumina ceramic material, known for its heat resistance and corrosion resistance. In a laser device, the ceramic body of the laser head is one of the core components, playing a crucial role.Laser ceramic ring of the laser head is a key component connecting the laser head and the laser body.

Contact Now