60W CO2 Laser Engraving Machine

Low cost, can completely replace the cutting and seal edge workers, the whole process, only one person operation;Automatic feeding, automatic complementing, automatic cutting, automatic sealing;Automatic typesetting, cutting accuracy of 0.2mm, fabric utilization rate of 98% or more;US automatic camera layout system, after the film can be reused;Single-layer cutting and multi-layer cutting for optional, customized shaped, only click the keyboard is ok, Perfect after-sales service system, can provide overseas international service.

CO2 laser engraving and cutting machine uses CO2 laser technology, featuring a laser generator, optical path system, worktable, cutting head, and cooling system. It offers high accuracy, fast scanning speed, and efficient energy conversion, minimizing material loss. Adjustable parameters allow versatility in cutting different materials. Its applications include industries, scientific research, medicine, advertising, and apparel.

Model | Format | Power |

5030E | 500*300mm | 50W |

7050E | 700*500mm | 60W |

9060E | 900*600mm | 80W |

Machine parameters

Laser type | Laser glass tube |

Laser power | 50W/60W/80W |

| Work platform | Blade platform + lifting platform (lifting height up to 280mm) |

Laser tube cooling method | Water cooling |

Control system | 5030E/7050E comes standard with the SmartDrive system 9060E comes standard with the SmartDrive system |

Motor and Drive | Stepper motor and driver |

Maximum carving speed | 0-48000mm/min |

Maximum cutting speed | 0-30000mm/min(Depends on the material) |

Positioning accuracy | ≤±0.01mm |

Minimum molded characters | Chinese characters 3*3mm, English 1*1mm |

Working voltage | 220V;50HZ/60HZ(Single-phase) |

Supports image and text format | Plt、dst、dxf、bmp、dwg、AI、las、support AutoCAD、CoreDraw |

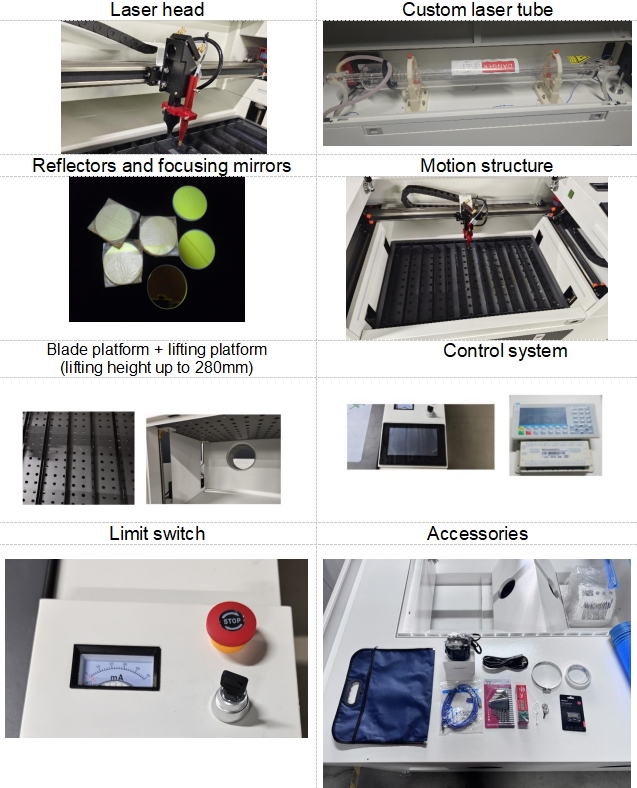

Machine configuration

Machine real shot photo

Machine installation and operation training

1. Our company will prepare the machine manual, circuit diagram and pre-installation documents and send them to the customer with the machine.

2. Our after-sales training will mainly be conducted online, with free online remote guidance on how to install and operate the machine. Our company has enough experience and skills to make customers satisfied with the quality of service. Before receiving the machine, customers can prepare the necessary tools based on the "Pre-Installation Preparation Instructions" provided by our company. Once the machine is received, customers can schedule training with our company at a convenient time. Our 50-person after-sales service team rotates 24 hours a day and will develop a training plan based on your appointment. The entire process of online training is free and is followed up until the customer has no questions about the operation of the machine.

3. Our company can also send engineers to the customer's factory to offer on-site guidance as needed.

Related Products

Submitted successfully

We will contact you as soon as possible

Related News

Submitted successfully

We will contact you as soon as possible