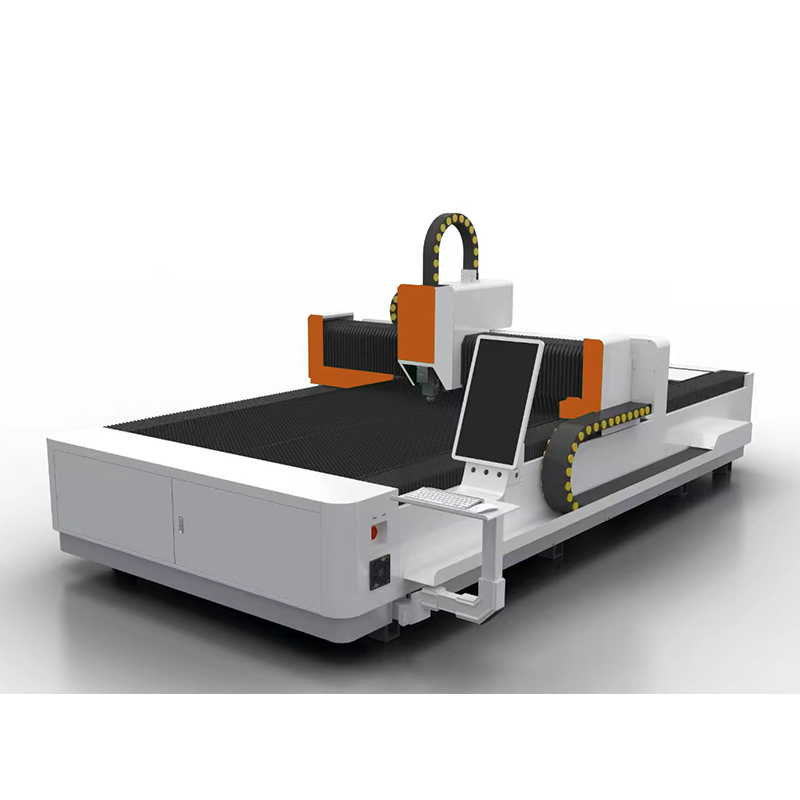

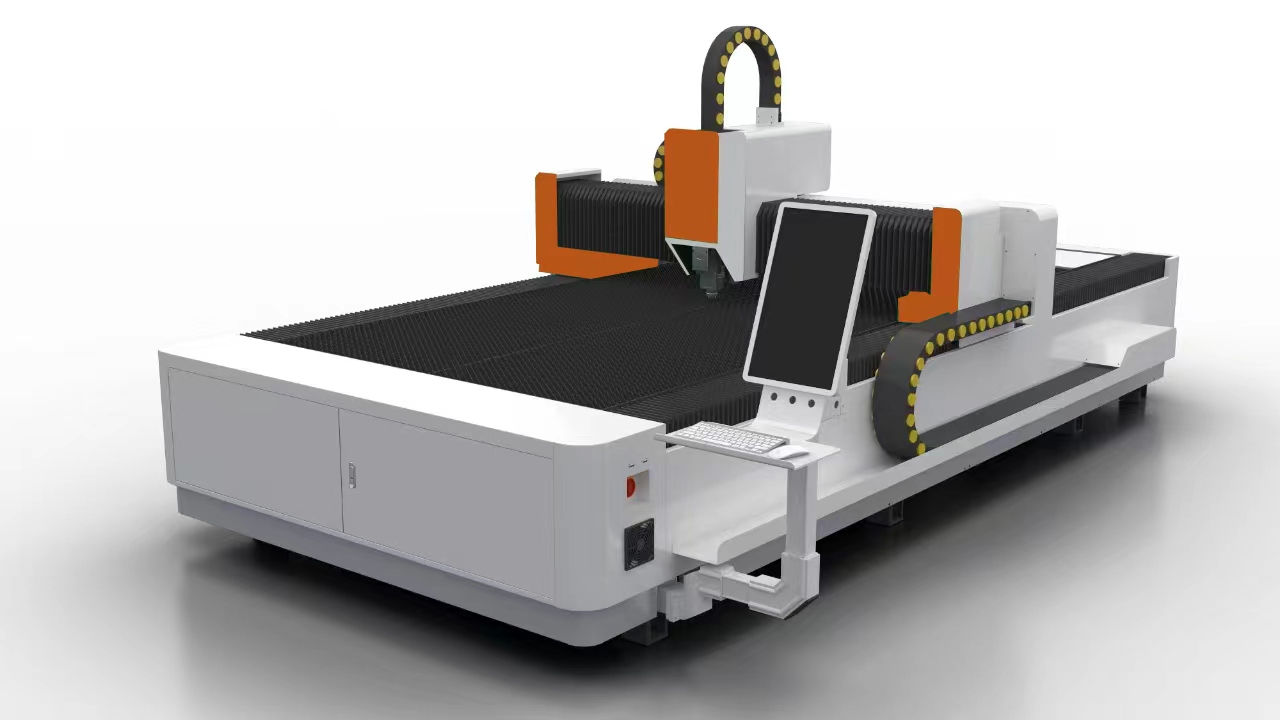

1.5KW Fiber Laser Flatbed Cutting Machine

High precision, fast speed, narrow kerf, minimal heat-affected zone, and smooth cut surface without burrs.

The laser cutting head does not come into contact with the material surface, preventing scratches on the workpiece.

The narrowest kerf, minimal heat-affected zone, extremely low local deformation of the workpiece, and no mechanical deformation.

Excellent processing flexibility, capable of processing any shape and also cutting tubes and other profiled materials.

Capable of performing deformation-free cutting on materials of any hardness, including steel plates, stainless steel, aluminum alloy plates, and cemented carbide.

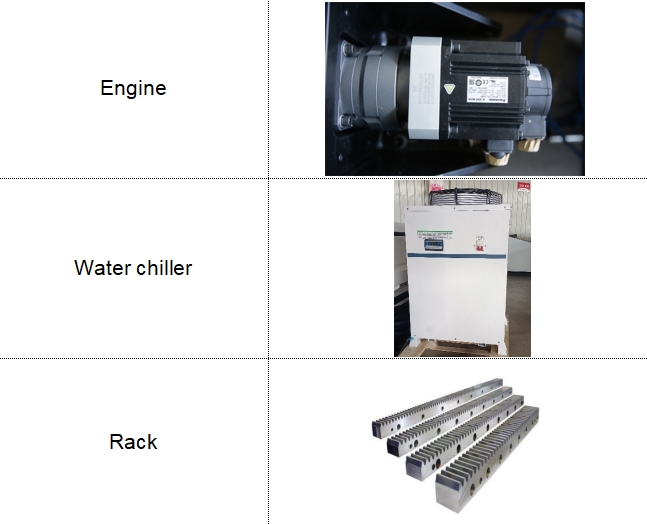

The fiber laser cutting machine is a type of laser cutting equipment that utilizes a fiber laser generator as its light source.

A fiber laser incorporates pumping material into the fiber. When a specific wavelength of laser emitted by a semiconductor laser is coupled, it causes the fiber to generate laser light, which is then focused onto the surface of the workpiece. The area of the workpiece illuminated by the laser spot locally melts and vaporizes instantaneously. By controlling the movement of the laser spot through a computer-controlled CNC mechanical system, automatic cutting is achieved. It is a high-tech equipment that integrates laser technology, CNC technology, and precision mechanical technology.

Compared to traditional CO2 laser cutting machines, fiber laser cutting machines offer faster cutting speeds and higher efficiency.

Fiber laser cutting machines demonstrate extremely high stability during operation.

The photoelectric conversion efficiency of fiber laser cutting machines can reach over 30%, making them more energy-efficient than YAG laser cutting machines.

Fiber laser cutting machines are capable of achieving high-precision cutting, meeting the demands of precision manufacturing.

Fiber laser cutting machines have a wide range of applications in the industrial manufacturing sector, particularly for cutting various metal materials such as carbon steel plates, stainless steel plates, aluminum alloy plates, and galvanized steel plates.

Model | 1530G |

Work area | 1500mm*3000mm |

Laser power | 1.5KW |

Control system | Osendic system |

X/Y Position Accuracy | 0.05mm |

X/Y repositioning accuracy | 0.03mm |

Maximum linkage speed | 85m/min |

Maximum acceleration | 0.8G |

Machine weight | 2800KG |

Power requirements | 380V, 50/60Hz |

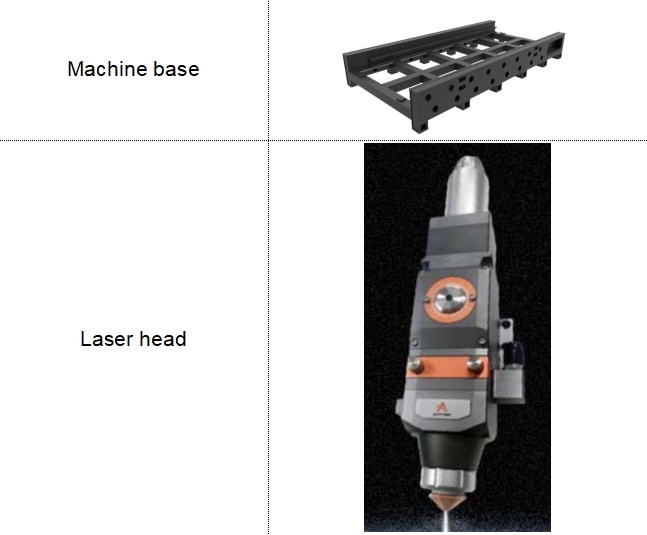

Core Configuration

Optional

Machine real shot photos

Machine installation and operation training

1. Before the customer receives the machine, our company will prepare the machine manual, circuit diagrams, and pre-installation documents to be sent along with the machine.

2. Our after-sales training will provide online remote guidance on how to install and operate the machine. Our company has sufficient experience and skills to ensure customer satisfaction with the quality of service. Before receiving the machine, the customer can prepare the necessary tools based on the "Pre-Installation Instructions" provided by our company. After receiving the machine, you can schedule a time to have the training with our company. Our after-sales service team of 50 people rotates 24 hours a day and will create a training plan based on your appointment. The entire process of online training is free and will be responsible until the customer has no questions about the operation of the machine.

3. Our company can also send engineers to the customer's factory for on-site guidance according to customer needs, which requires the customer to bear the round-trip airfare, accommodation expenses, and a fee of 2,000 yuan per day for the engineer.

Related Products

Submitted successfully

We will contact you as soon as possible

Related News

Submitted successfully

We will contact you as soon as possible