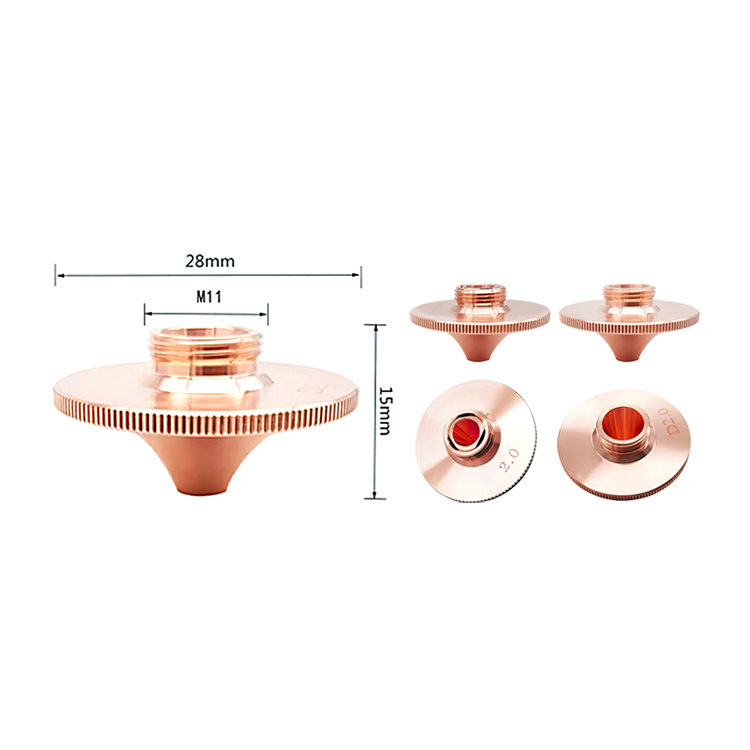

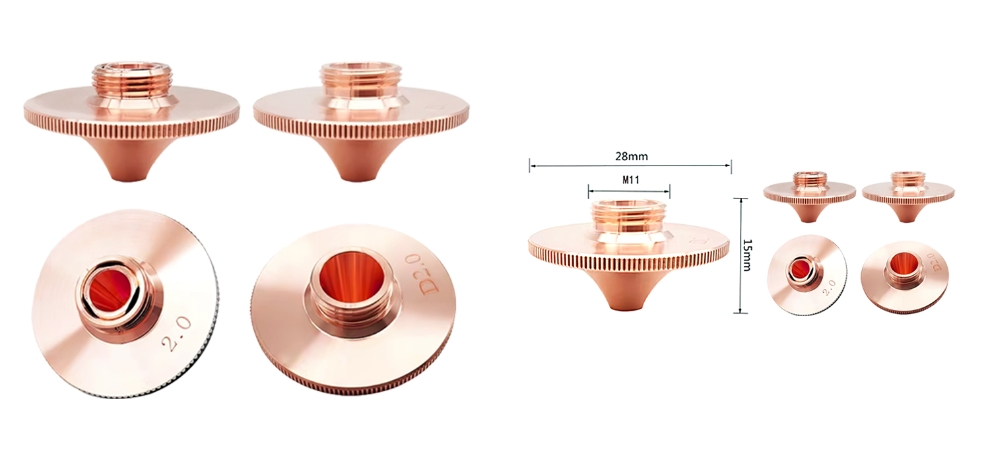

28mm Double Style Laser Nozzle

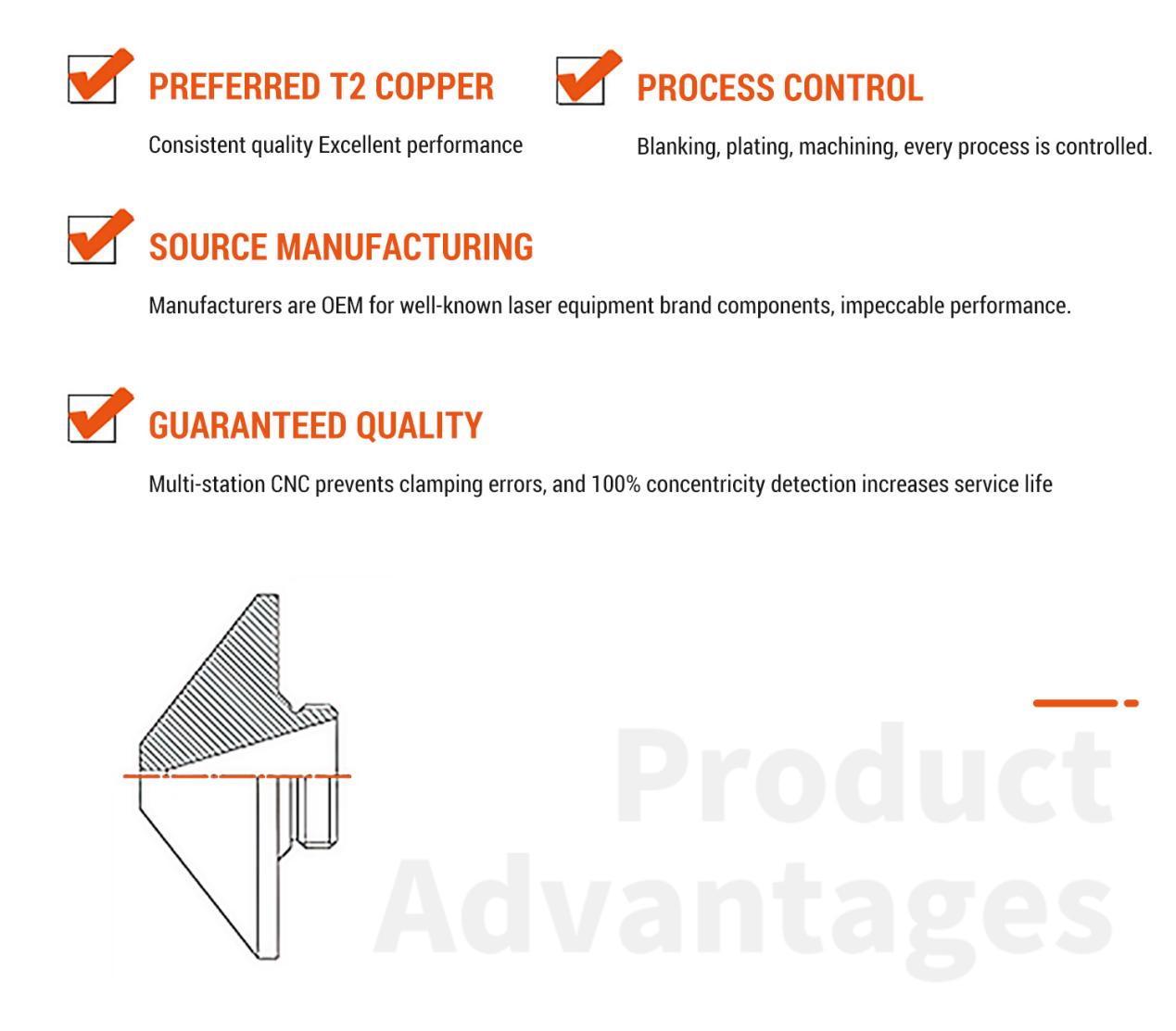

Consistent quality Excellent performance;Blanking, plating, machining, every process is controlled;Manufacturers are OEM for well-known laser equipment brand components, impeccable performance;Multi-station CNC prevents clamping errors, and 100% concentricity detection increases service life.

The laser nozzle is vital in laser cutting, managing distance, directing gas flow, creating high pressure for faster cutting, removing slag, and protecting lenses. It impacts cutting quality directly.

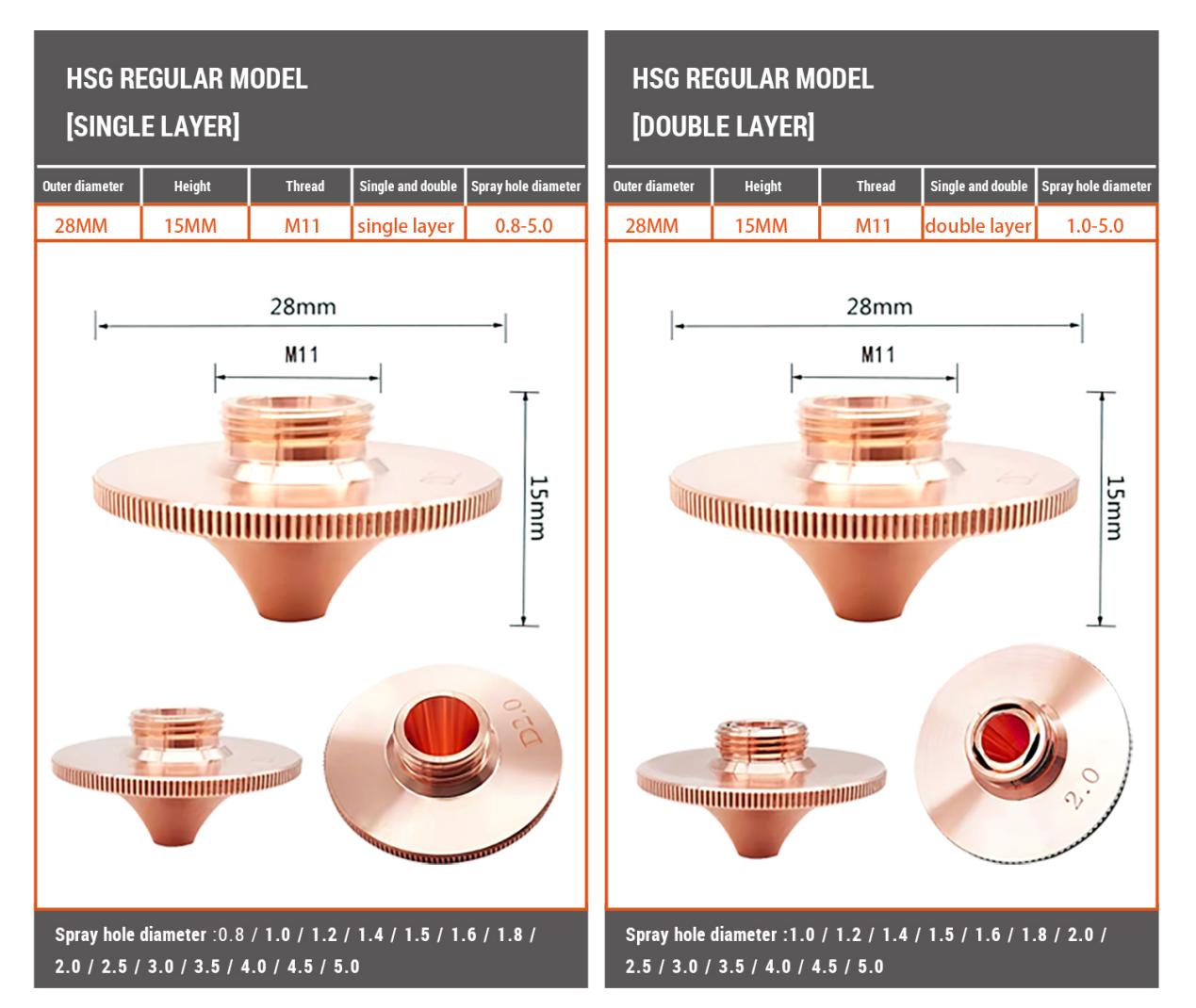

Types of nozzles include:

Single-layer: Uses nitrogen for melting cutting of stainless steel and aluminum alloy.

Double-layer: Uses oxygen for oxidative cutting of carbon steel.

Aperture size affects cutting quality:

Small aperture: Best for thin plates, finer surface but may leave slag at corners.

Large aperture: Suitable for thick plates, stable cutting but less lens protection, risking damage from sparks.

Coaxiality between the nozzle outlet and laser beam is critical, especially for thick workpieces, ensuring better cutting results.

Related Products

Submitted successfully

We will contact you as soon as possible

Related News

Submitted successfully

We will contact you as soon as possible