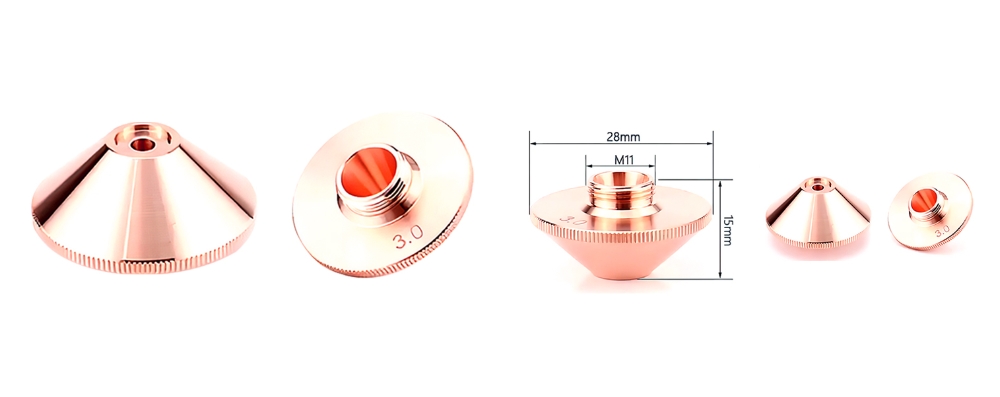

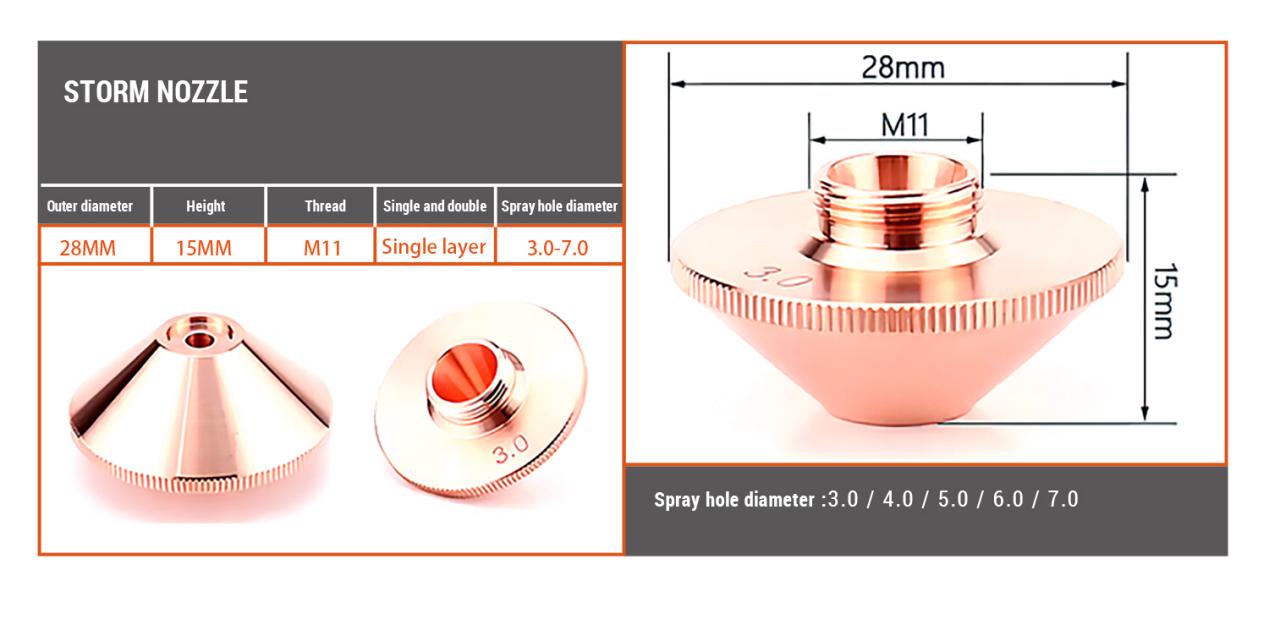

28mm High Power Laser Nozzle

Consistent quality Excellent performance;Blanking, plating, machining, every process is controlled;Manufacturers are OEM for well-known laser equipment brand components, impeccable performance;Multi-station CNC prevents clamping errors, and 100% concentricity detection increases service life.

The laser nozzle is accountable for retaining the distance between the laser head and the workpiece, guiding the auxiliary fuel to ignore easily via the workpiece being cut, and growing excessive strain at the nozzle outlet to speed up the reducing speed. It additionally consists of away molten slag and protects the inside lenses of the laser head. It is an essential phase of the laser slicing technique and immediately determines the pleasant of laser cutting.

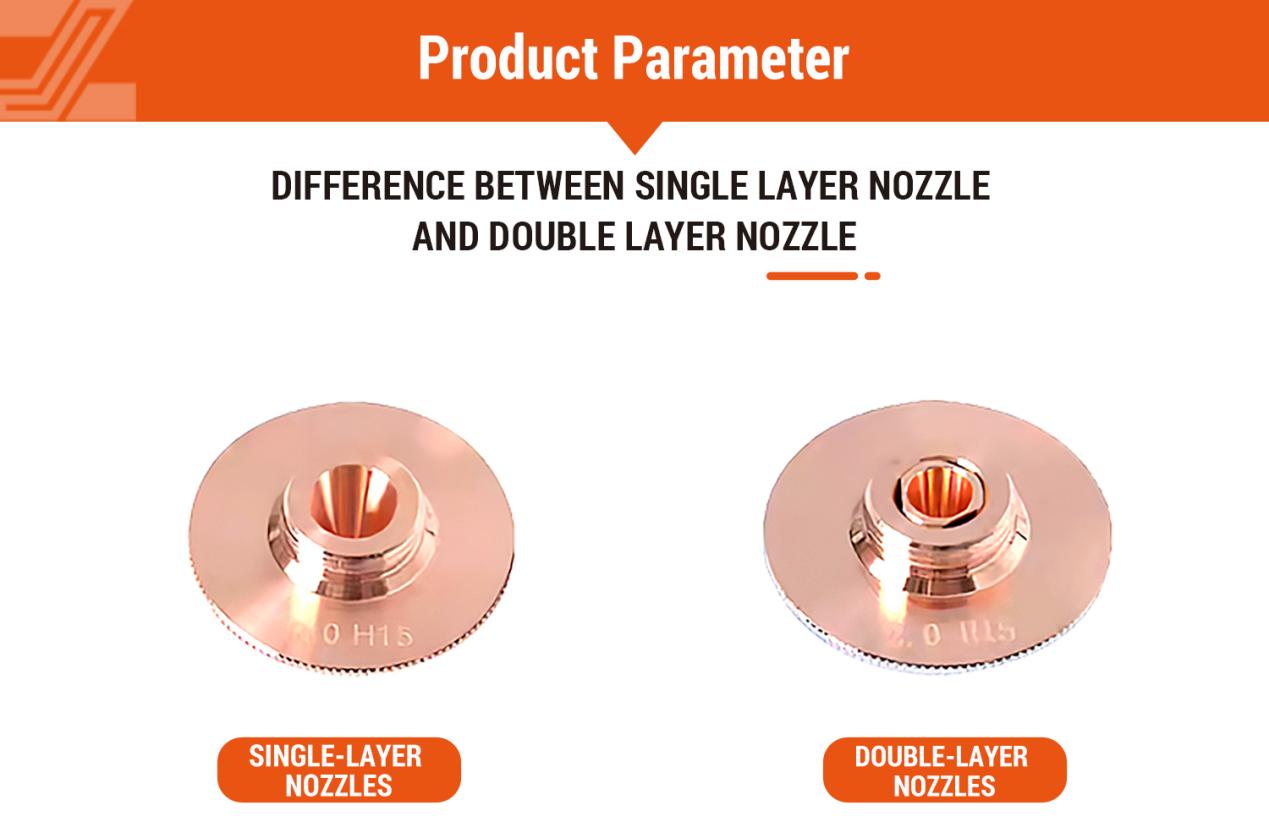

Single-layer nozzle: Nitrogen is used as the auxiliary gas. It is by and large used for melting slicing and is appropriate for slicing substances such as stainless metal and aluminum alloy.

Double-layer nozzle: Oxygen is used as the auxiliary gas. It is chiefly used for oxidative slicing and is appropriate for slicing substances like carbon steel.

The aperture dimension of the laser nozzle has a huge have an effect on on the slicing quality:

Small aperture nozzle: Suitable for skinny plate cutting, succesful of accomplishing a finer reducing surface, however there may additionally be molten slag at the corners.

Large aperture nozzle: Suitable for thick plate cutting, with a massive fuel diffusion location and slower gasoline flow, ensuing in extra steady cutting. However, the large the aperture, the poorer the safety for the focusing lens, as the possibility of molten fabric sparks splashing upwards increases, probably shortening the lifespan of the lens.

The coaxiality between the nozzle outlet gap and the laser beam is one of the necessary elements affecting the pleasant of the cutting. Especially when reducing thicker workpieces, the have an impact on of coaxiality turns into greater significant. Therefore, it is critical to modify the coaxiality between the nozzle core and the laser to acquire a higher reducing section.

Related Products

Submitted successfully

We will contact you as soon as possible

Related News

Submitted successfully

We will contact you as soon as possible