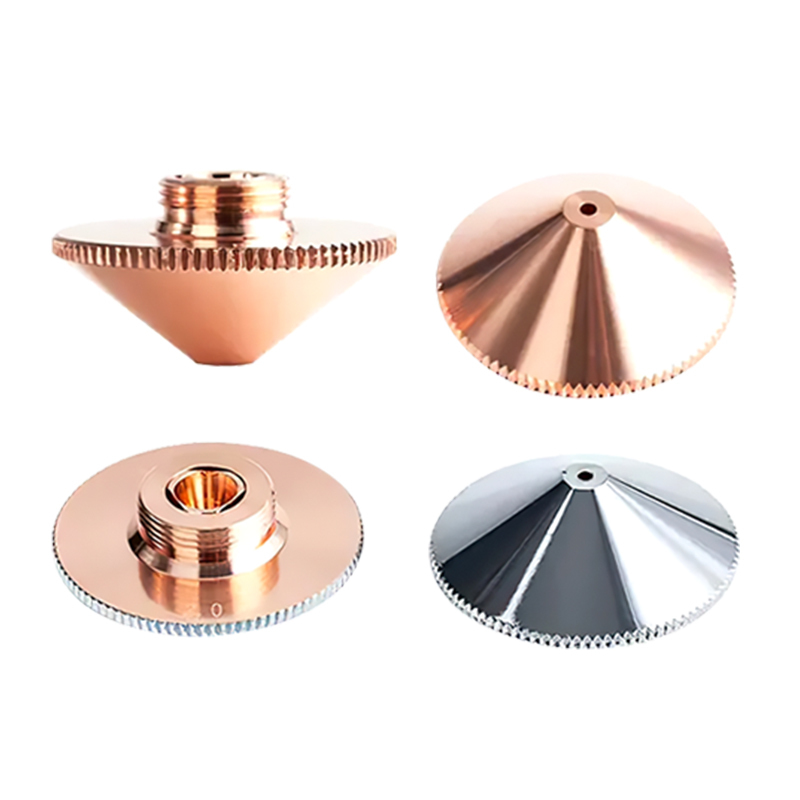

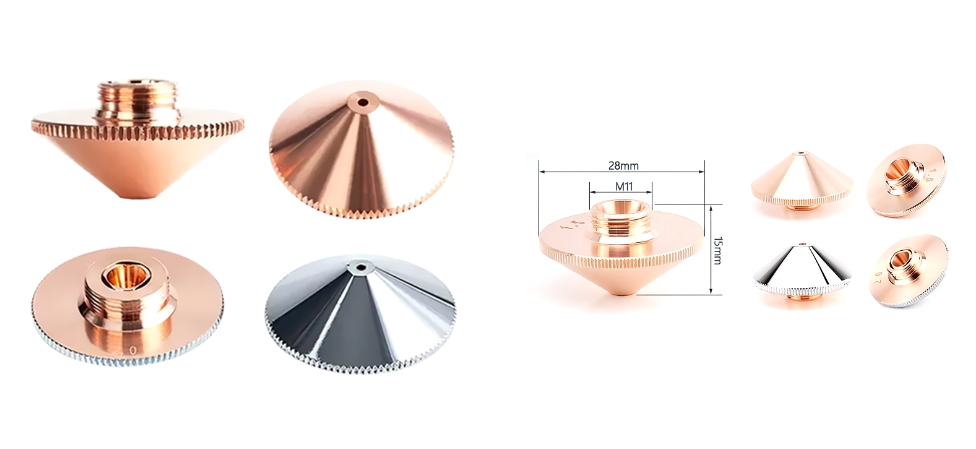

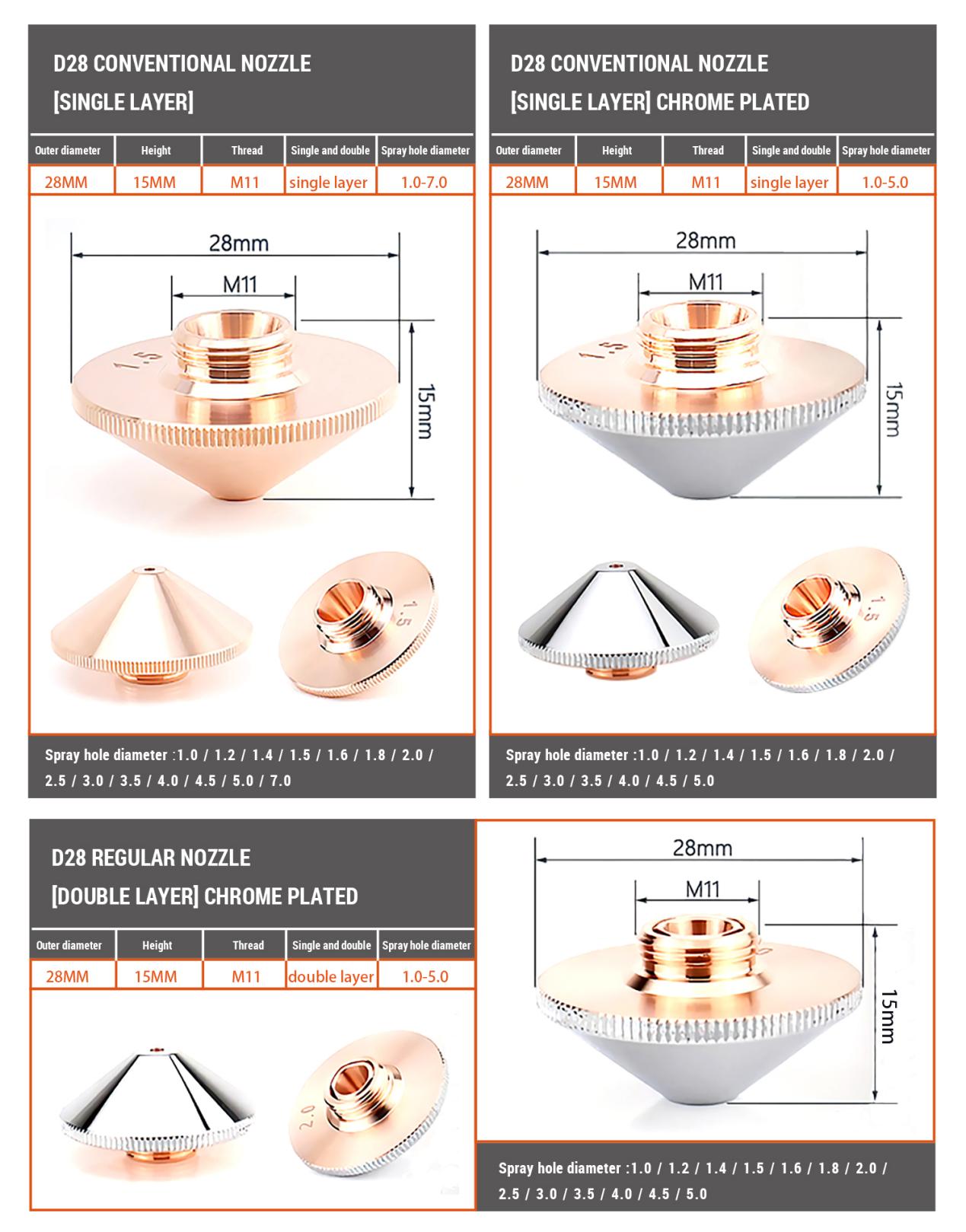

28mm Standard Single Style Laser Nozzle

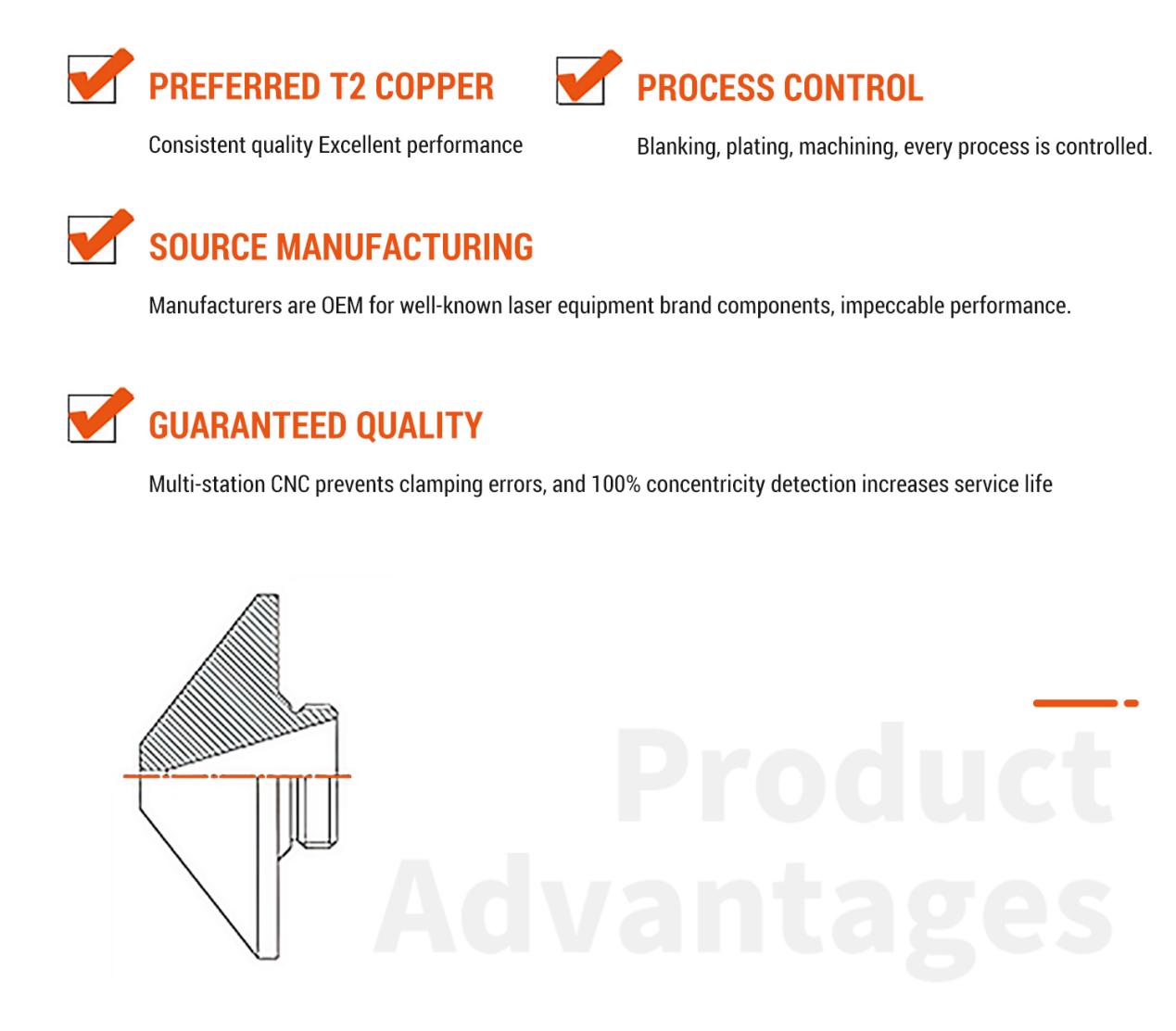

Consistent quality Excellent performance;Blanking, plating, machining, every process is controlled;Manufacturers are OEM for well-known laser equipment brand components, impeccable performance;Multi-station CNC prevents clamping errors, and 100% concentricity detection increases service life.

Control the focusing position of the laser beam:

The nozzle can precisely control the focusing position of the laser beam on the workpiece surface, ensuring that the laser energy is accurately applied to the area that needs to be cut.

Accelerate the laser beam:

Through the design of the nozzle, the laser beam can be accelerated, causing the irradiated area to melt and vaporize, forming a cutting gap.

Guide the gas flow:

The nozzle can guide auxiliary gases (such as nitrogen, oxygen, etc.) to pass smoothly through the workpiece being cut, and form high pressure near the nozzle outlet, which accelerates the cutting speed while carrying away slag and heat generated during cutting, thereby protecting the internal lens of the laser head.

Protect the focusing lens:

The rapid ejection of auxiliary gas through the nozzle can effectively prevent debris such as molten material from rebounding upwards, thus protecting the focusing lens from damage.

Improve cutting quality:

The geometric shape and size of the nozzle have a significant impact on cutting quality. By selecting appropriate nozzle types and aperture sizes, the gas flow and laser beam focusing effect during cutting can be optimized, thereby improving cutting accuracy and cross-sectional quality.

Different cutting materials require different nozzle types and auxiliary gases. For example, for metallic materials such as stainless steel, nitrogen is usually chosen as the auxiliary gas, and a corresponding nozzle type is selected.

The thickness of the workpiece is also an important factor in selecting the nozzle. As the thickness of the workpiece increases, a nozzle with a larger aperture is needed to ensure sufficient auxiliary gas flow and cutting speed.

The coaxiality between the nozzle outlet hole and the laser beam is one of the important factors affecting the quality of the cut. Therefore, it is necessary to regularly check and adjust the coaxiality between the nozzle center and the laser during use to obtain a better cutting surface.

Related Products

Submitted successfully

We will contact you as soon as possible

Related News

Submitted successfully

We will contact you as soon as possible