1000W Laser Welding Protective Lens

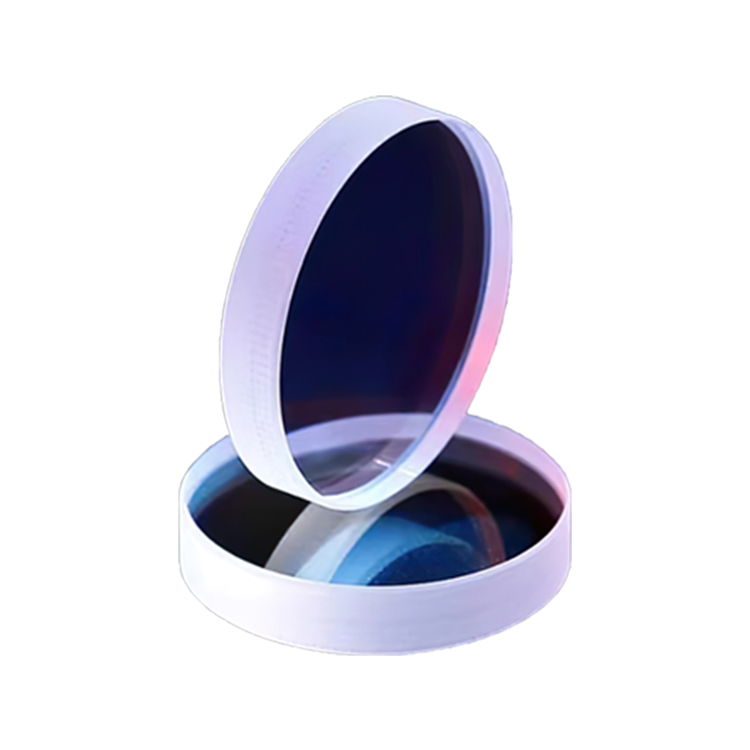

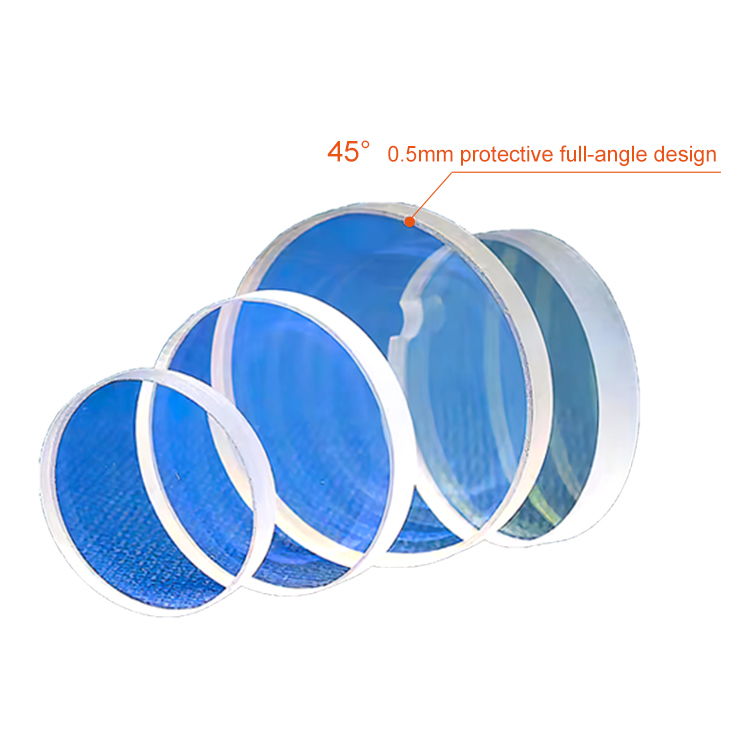

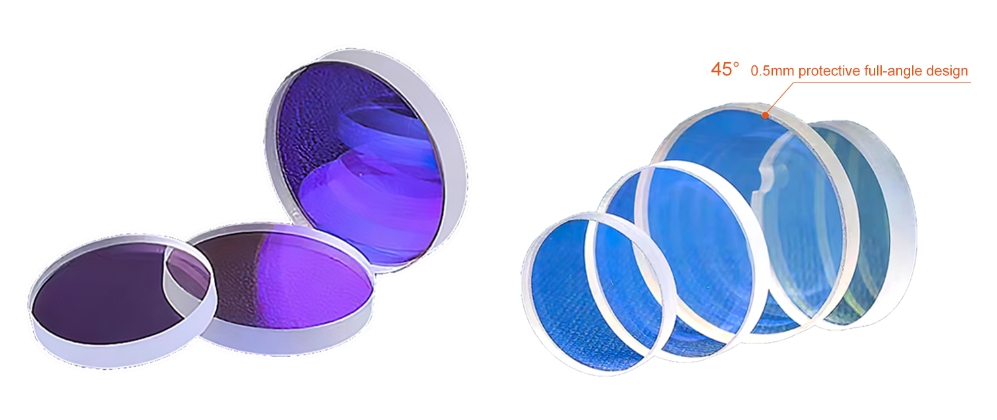

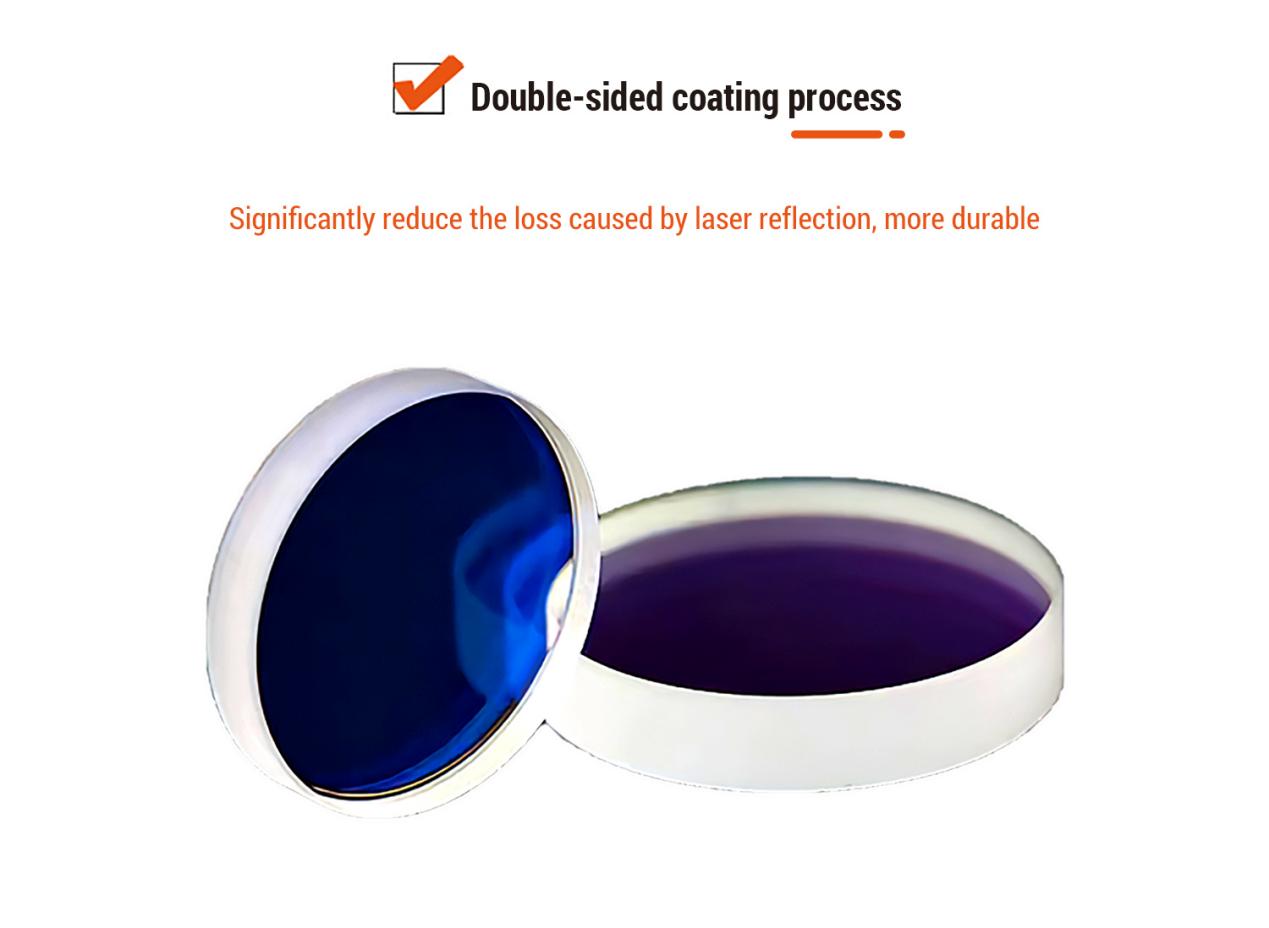

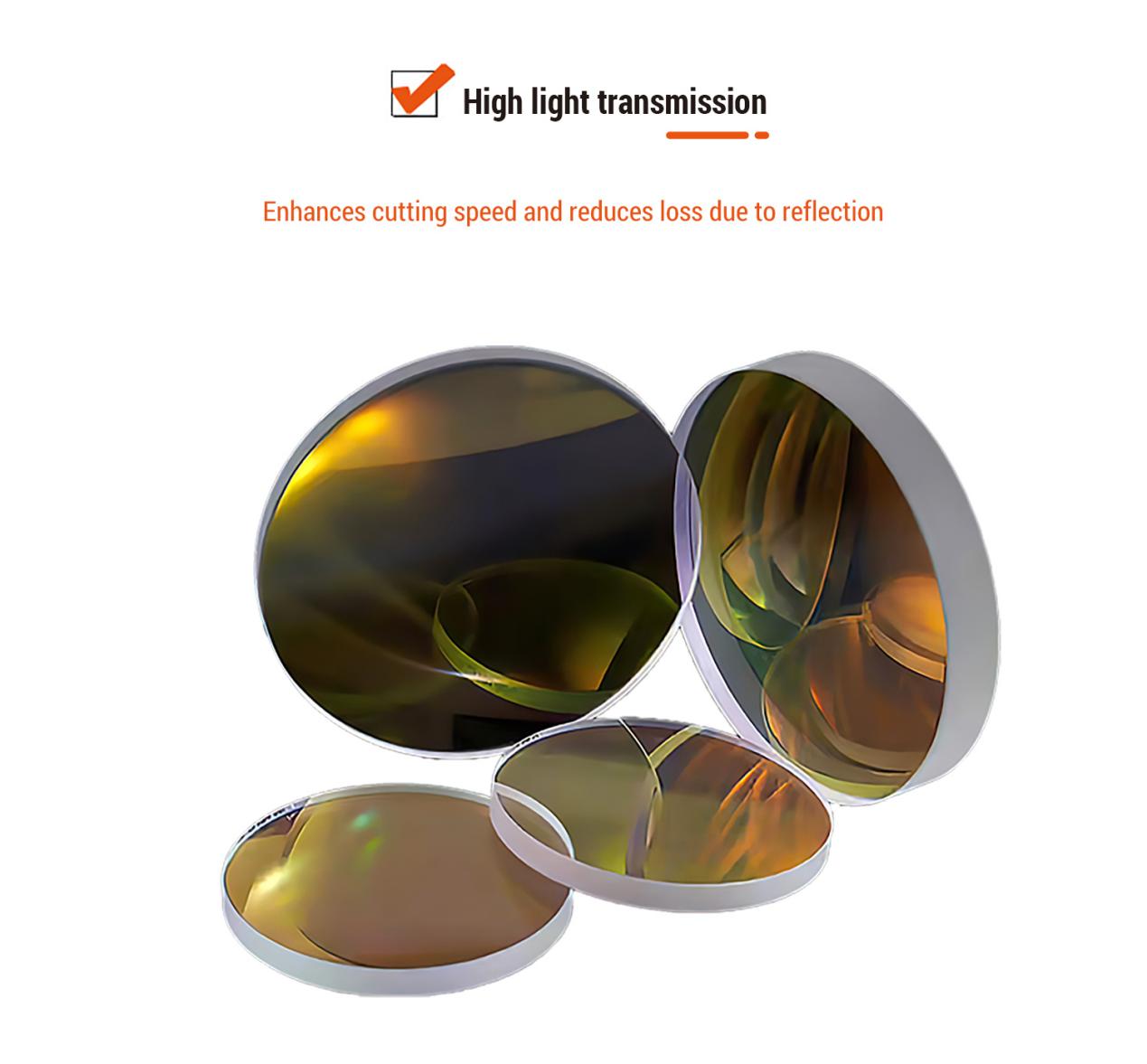

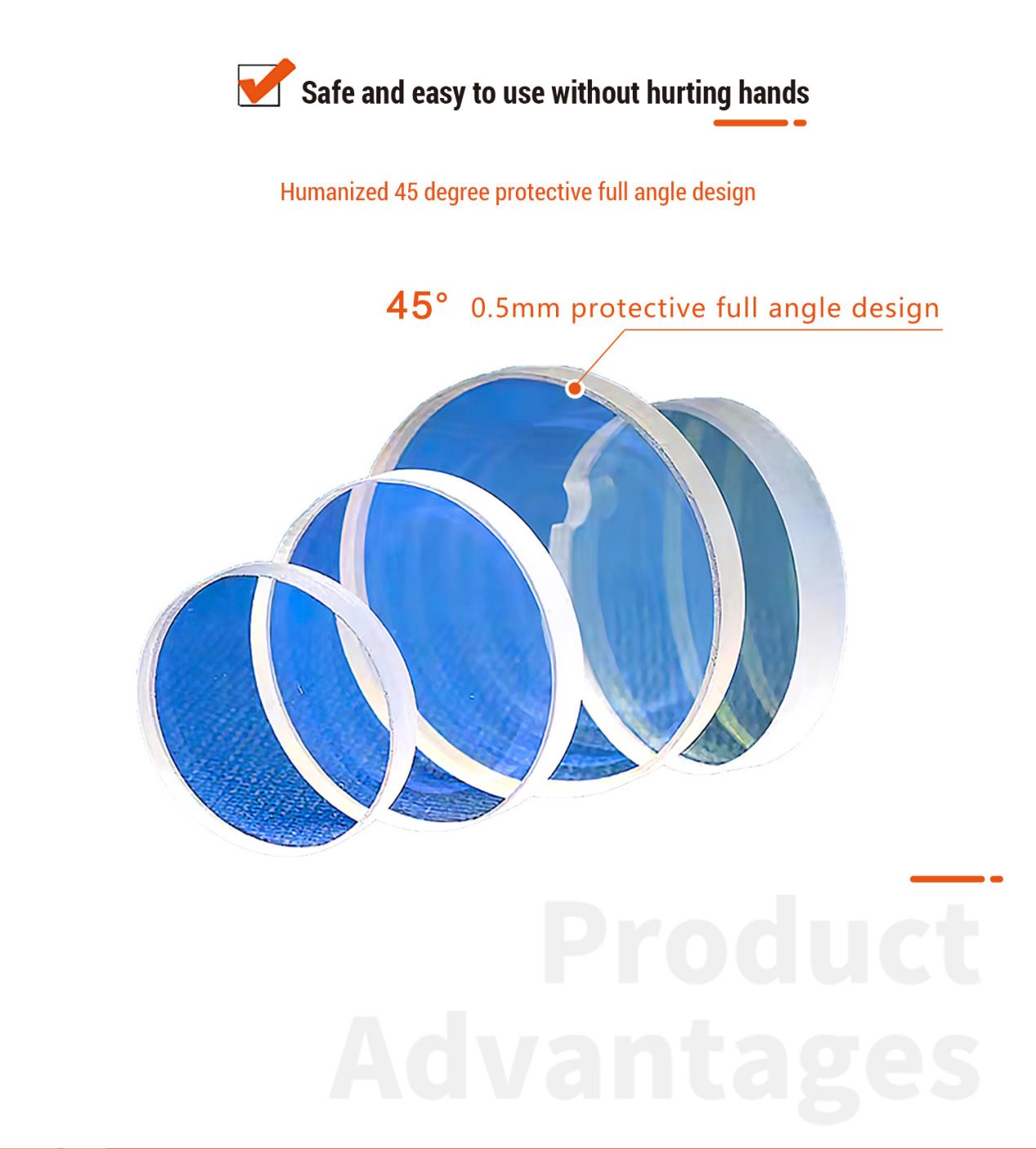

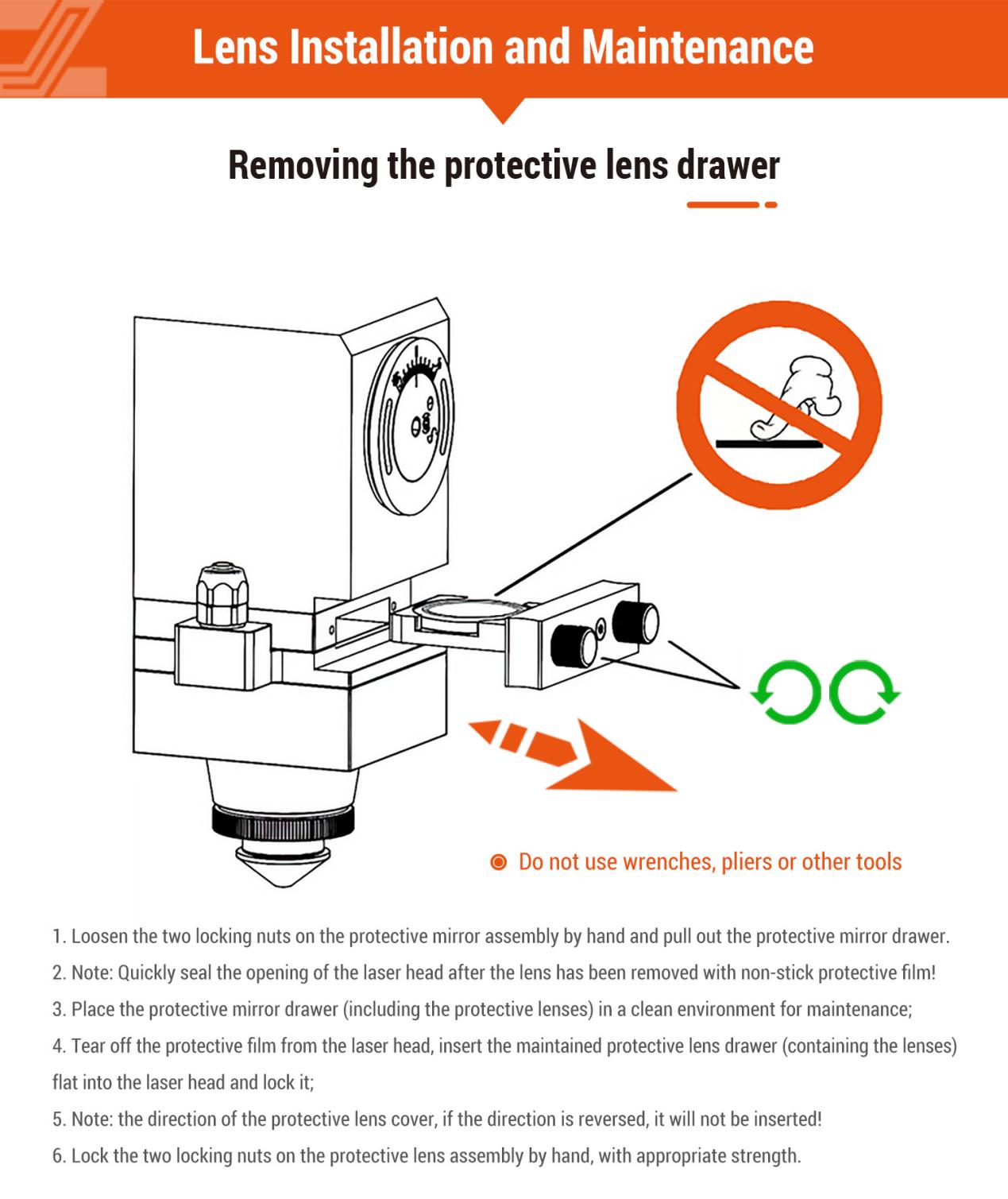

Excellent optical, thermal and mechanical properties;Significantly reduce the loss caused by laser reflection, more durable;Enhances cutting speed and reduces loss due to reflection;Humanized 45 degree protective full angle design.

Laser protective lenses, also known as laser window panes, optical window panes, or laser dust-proof lenses, are crucial optical components specifically engineered for use in laser devices. Their primary function is to safeguard human eyes and critical components within laser equipment from laser radiation and other potential hazards, such as high-temperature splashes and dust.

These lenses have a wide range of applications in various laser processing equipment, including laser cutting machines, welding machines, marking machines, and engraving machines. They also play a vital role in fields like laser medicine and laser experiments.

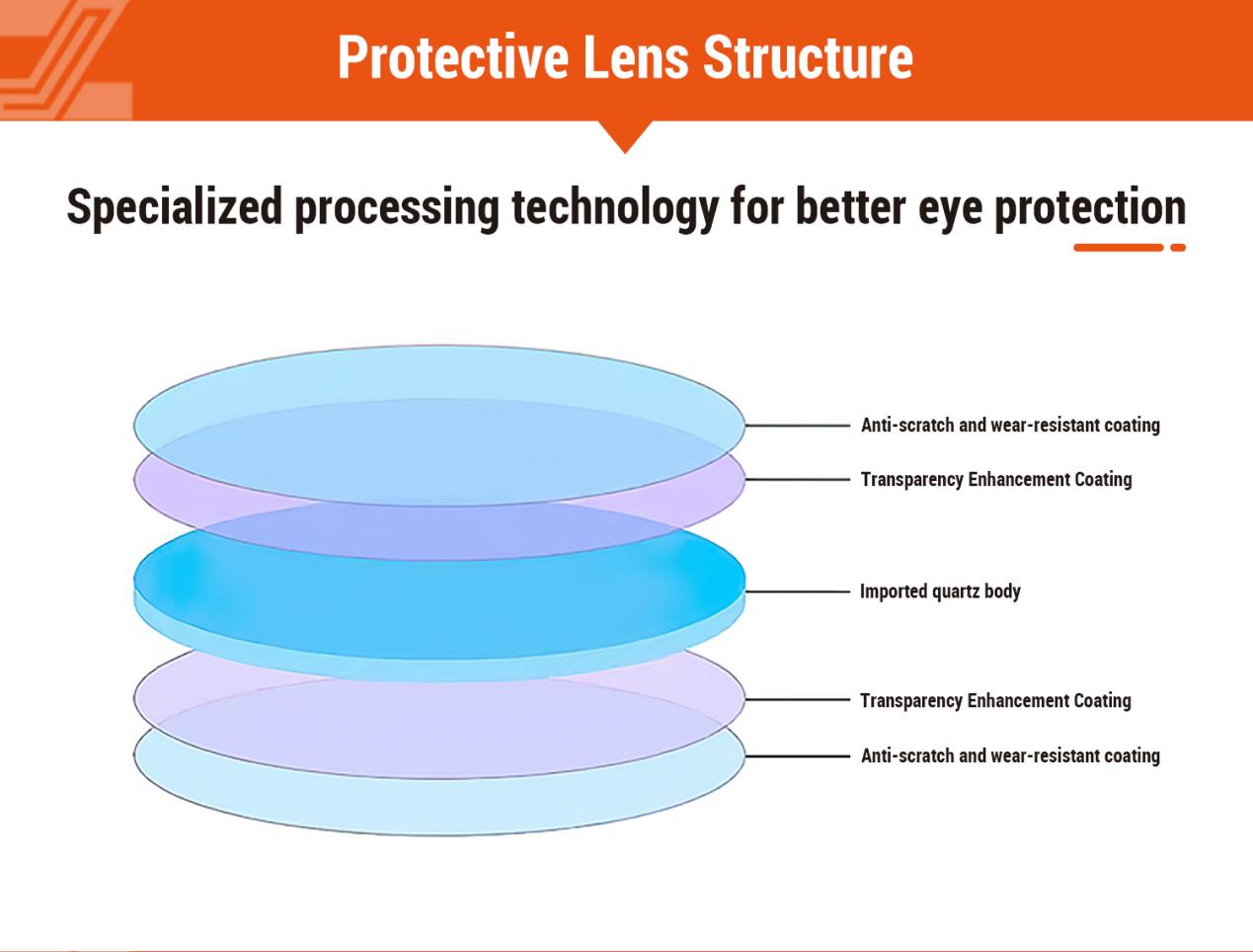

Key performance indicators of laser protective lenses include transmittance, surface accuracy, thickness, parallelism, and substrate material. Transmittance determines the lens's ability to transmit laser light, with high transmittance reducing laser loss and enhancing processing efficiency. Surface accuracy refers to the flatness of the lens surface, directly impacting imaging quality and laser focusing effect. Therefore, high standards of surface accuracy are essential.

Thickness is another crucial factor affecting lens performance. An appropriate thickness ensures sufficient strength and stability, while avoiding excessive thickness that could lead to laser loss and increased costs. Parallelism refers to the degree of parallelism between the lens surface and the direction of light propagation, ensuring a stable laser direction during transmission and improving processing accuracy.

The substrate material determines the physical and chemical stability of the lens. Common substrate materials include glass, quartz, and crystals, each with unique advantages and disadvantages requiring selection based on specific application scenarios.

In summary, laser protective lenses are essential for safeguarding human eyes and critical components within laser equipment, with key performance indicators and substrate material playing crucial roles in their effectiveness.

Style | Material | Diameter | Thickness | Transmittance | Wavelength |

1000W-4000W | Imported quartz | 18 | 2 | 99.9% | 1064 |

20 | 2 | 99.9% | 1064 | ||

20 | 3 | 99.9% | 1064 | ||

20 | 4 | 99.9% | 1064 |

Related Products

Submitted successfully

We will contact you as soon as possible

Related News

Submitted successfully

We will contact you as soon as possible