20.5mm Laser Sealing Ring

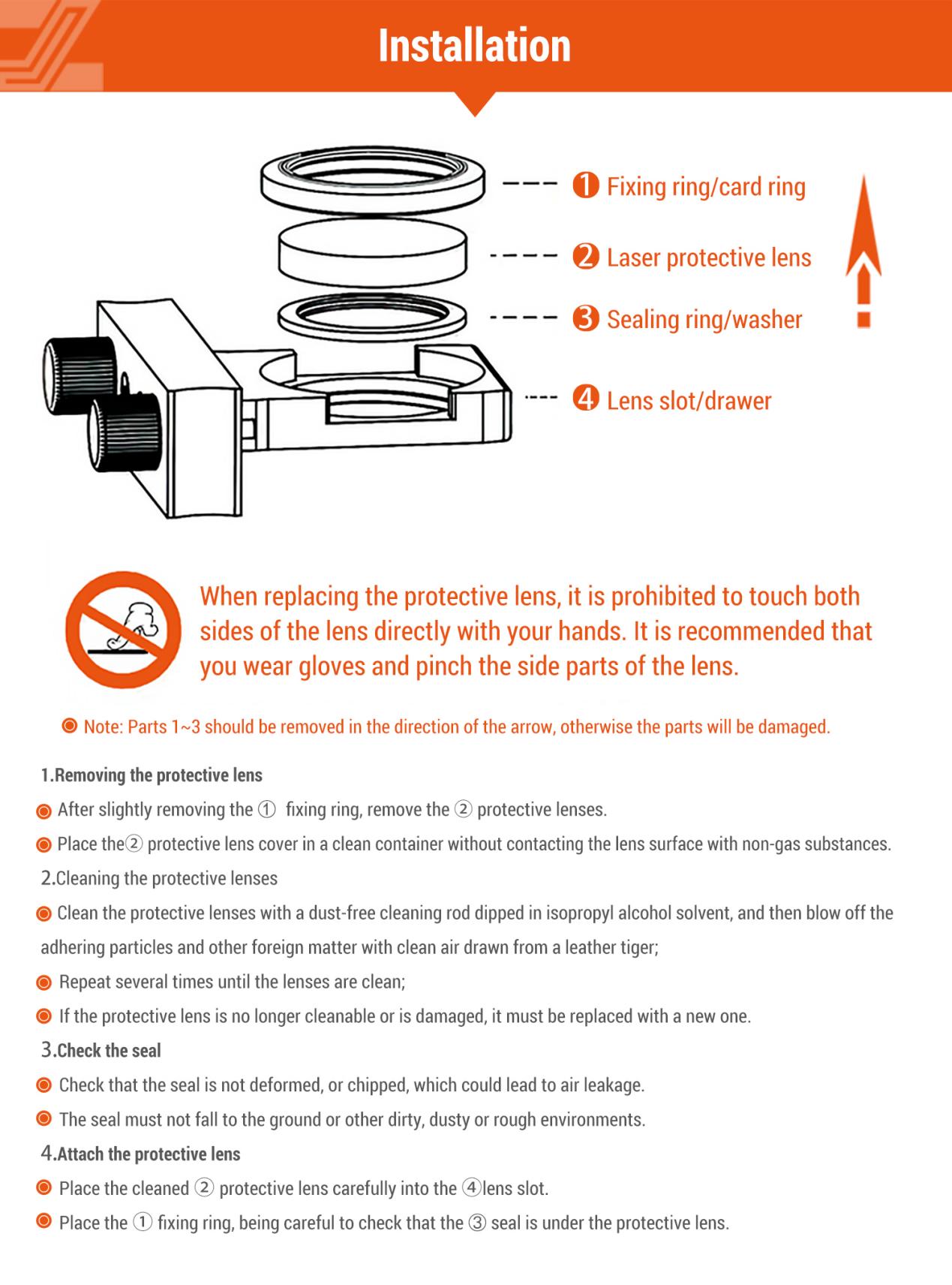

Imported PTFE material,Stainless steel Spring,Good sealing, smooth surface, low friction and good leakage prevention.

Laser sealing ring consists of a corrosion-resistant spring (typically a stainless steel spring) and a U-shaped filler material (usually PTFE or other high-performance polymeric materials) that together form a sealing ring. This seal design combines the properties of metal and plastic (or polymeric material) to provide excellent sealing effect.

During operation, laser sealing ring maintains a pre-compressed sealing state, and due to the actuating effect of the spring, it can overcome slight eccentricities in the metal mating surfaces and wear on the sealing lips, thereby continuously maintaining the expected sealing performance.

Made of metal and plastic (or polymeric material), laser sealing ring possesses high strength and rigidity, meeting the requirements for high-precision sealing.

Both the filler material (such as PTFE) and the metal spring exhibit excellent corrosion resistance, enabling them to maintain stable sealing performance in harsh environments.

Thanks to its outstanding sealing effect and wear resistance, laser sealing ring has a relatively long service life.

Laser sealing ring is widely used in various applications requiring high-precision and reliable sealing, such as laser equipment, aerospace, petrochemicals, and other fields.

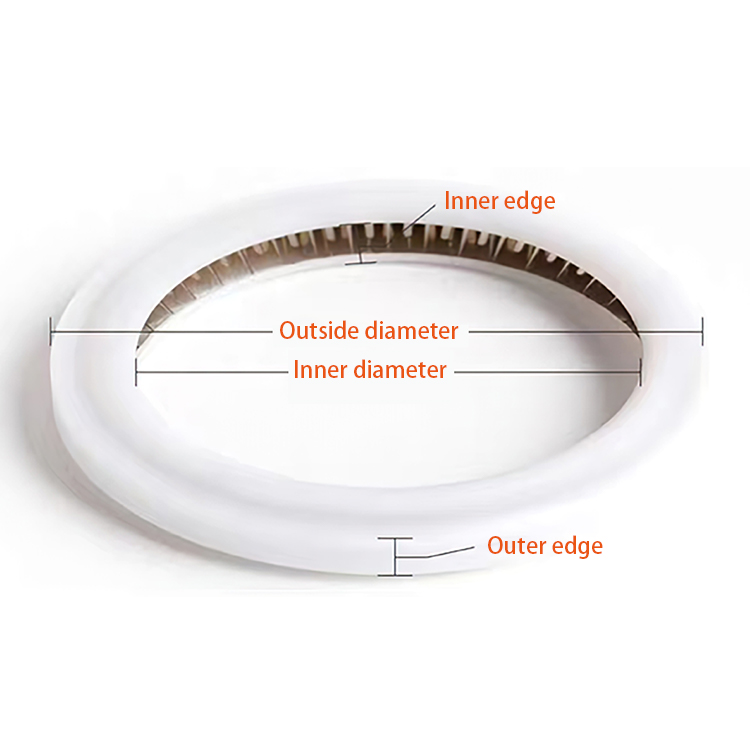

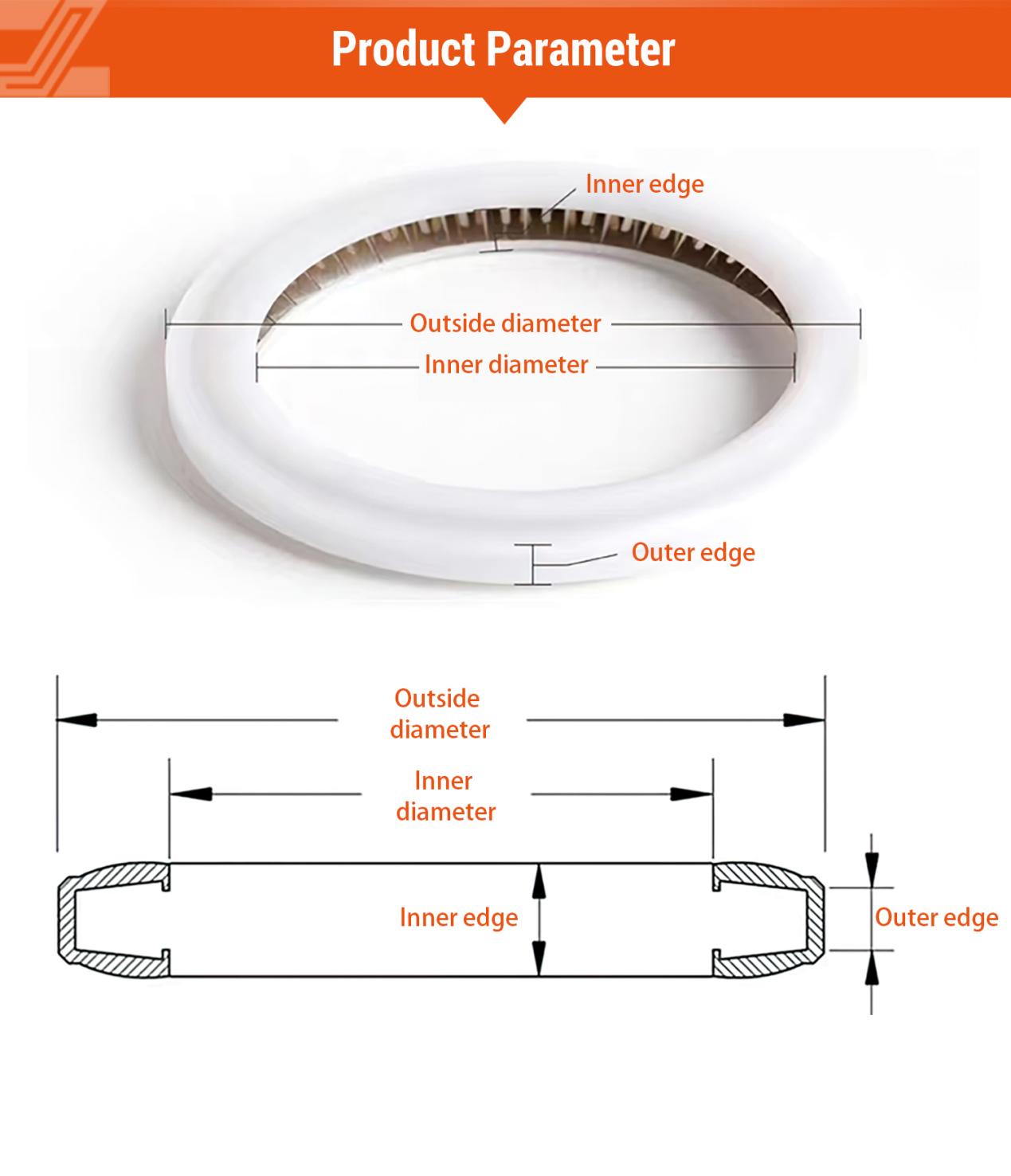

Style | Outside diameter | Inside diameter | Inner edge | Outer edge |

Kirin WSX AoSen Laser Sealing Ring | 20.5 | 16 | 2.5 |

Related Products

Submitted successfully

We will contact you as soon as possible

Related News

Submitted successfully

We will contact you as soon as possible